Bryan Griffen is President of Griffen Executive Solutions LLC.

Sean Riley: Hi, my name is Sean Riley. Welcome to the ProFood World video interview series. Today, we're diving into the latest and greatest in food manufacturing with industry leaders who know the ins and outs of what's important and what you need to know now in food processing operations. Whether you're here for some fresh insights or just curious about what's important for your operations, you're in the right place. Let's jump right in with Bryan Griffen.

Bryan Griffen: Thank you, Sean. I'm Bryan Griffen. I'm a 30-year veteran of the fast-paced consumer goods processing and packaging industry. I've worked across the globe in all phases of manufacturing from R&D to corporate operations, and also in the factories. I now provide executive coaching and consulting to help businesses optimize performance and achieve sustainable growth, and that's what we're going to talk about a little bit today.

On today's ProFood World interview, we're talking with Joe Zembas. Joe started his career at Procter & Gamble (P&G) where he spent 24 years working in manufacturing plants in Pennsylvania, Italy, England, Maine, and Kansas City. While in Kansas City, P&G divested its coffee business that Joe was a part of, and that was sold to the JM Smucker Company.

He then spent 14 years with Smucker's, moving from Kansas City to various corporate roles and finally to a plant in Alabama. Joe retired from Smucker's and returned to Procter & Gamble two years ago and is now managing capital projects for P&G. During his illustrious career, he has built two greenfield factories and managed approximately $1 billion of capital investment.

In addition to Joe's capital and project leadership roles, Joe has also spent most of his career in the manufacturing plants, where he led the installation of OEE tracking systems in several plants and business units, in addition to spending significant time improving OEE results. So welcome, Joe.

Joe Zembas: Hi Bryan. How are you doing today?

Bryan Griffen: Pretty good. What's with the hunting vest?

Joe Zembas: Oh, I happen to be in the middle of a hunting vacation and your call caught me right in the middle of a wonderful week in the woods. So here I am.

Bryan Griffen: Well, thank you for taking the time to join me today in the middle of your hunt. Hopefully I can keep this short and sweet, and maybe even keep the hunt alive with a few relevant analogies.

Joe Zembas: Good. Hopefully you'll bring me some good luck.

Bryan Griffen: I want to kick things off with the basics. Just like if we were building camp before we join the hunt. Can you break down what operational equipment effectiveness, or OEE, is for us in terms of its main components?

Joe Zembas: Sure. So first off, you've really got to look at availability. In a manufacturing environment, that's looking at what is the market demand for the product you're producing on that piece of equipment and therefore what's the run schedule going to be?

It's no use running a line 24/7, 365, if you've only got eight-hour or five-day kind of volume. You know, similarly, in hunting, you could be seeing all kinds of deer throughout the summer when the season's not going, but you get out there for that one week of the season, that's when it really matters.

Bryan Griffen: They all disappear.

Joe Zembas: Yes. So you really got to look at the key opportunity times and make sure that you're comparing, you know, the right basis. The second area is really performance, and that is within that time frame where you are really looking to deliver. Is the machine running as it should? You know, breakdowns, minor stops, all those kind of things play into that performance segment.

So it's really important during that to be able to troubleshoot those items and be able to identify those. And that's really where a lot of the focused improvement type work, continuous improvement type work needs to be addressing is those performance outages.

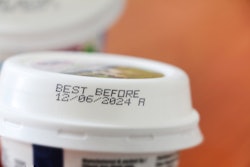

And then the last one, which sometimes gets masked because the product leaves the line and is assumed to be good, but then you end up having to scrap a lot of product from the warehouse or recall product because quality is just not there. So, the quality portion is very important, similar to being in the deer stand looking for all of the bucks and only does come by. You've got to make sure that you're making what the market is really going to be able to sell and what's going to really be the focus of your operation.

Bryan Griffen: Got it, okay. So, we hear a lot these days about tracking OEE. And it seems with all the recent advancements in IoTT, artificial intelligence, et cetera, that it would be similar to trading in an old traditional scope for a nice high-tech laser-sighted scope. How have you seen tracking OEE change over the years and what's the difference it makes on the hunt for productivity?

Joe Zembas: Okay, well, continuing with the hunting analogy, our ancestors used to figure out which way to go depending on the moss on the side of a tree or other very rudimentary types of systems. Similarly, tracking what's coming off of a production environment, you can do very manually. You know, very simple tick charts, a tablet, et cetera, are very manual ways to do it.

Continuing with the navigation analogy, the compass came along and made it a lot more effective for, you know, Columbus to sail the ocean blue and all those kind of things. In the manufacturing world, I've seen products on the market for $50 that you could put on the machine and it'll simply track time running versus time not running. A very simple, rudimentary way to evaluate and track what you're doing from an OEE standpoint.

And then just like in today's world, you can use a GPS tracking app to go find your way through the woods, find your way exactly to where you sat yesterday when you saw the big buck and didn't get a shot. There's a lot of modern technology out there where you're pulling tags from PLCs and putting them in databases and being able to then parade of those tags or parade of those causes relative to certain categories, like mechanical failures, electrical failures, starved for incoming product, blocked, unable to move the product past the machine, et cetera.

So you can go up and down the spectrum from very manual to very high tech. And it's really just a matter of what the business can afford and what's going to provide value.

Bryan Griffen: Okay. Well, that makes a lot of sense. Well, let's say that the equipment that we're looking at is acting like that one buck, that every year it keeps slipping through. You see it, but you never get the shot off, and every year you watch that rat grow.

So what are some of the common OEE troublemakers that you've seen, and what are the strategies for catching and improving them?

Joe Zembas: Okay, we'll run down through availability and performance and quality again. So from an availability standpoint, it could be very simple things like staffing levels, like starving or blocking the machine by not providing the raw material to it or ingredients to it, or it unable to move stuff on down through the system.

From a performance standpoint, there are, all kinds of different losses that you see, but things will be very machine dependent. If you've got a very rudimentary machine, it may simply just be a jam here or there. If you've got a high-tech servo-driven multi-access machine, there might be much more difficult problems to troubleshoot and solve. And then from a quality standpoint, some machines will automatically reject off-quality things because of sensors up and down the machine, or some of those will simply be done offline afterward.

So, unfortunately like that big buck, sometimes it's back at the kitchen table and everything's already done and over with. And that's when you're finding out that the quality of the product was not where it needed to be. Or you check your camera and it says, Oh, look, the deer just walked by now, 10 minutes after you left the stand.

Bryan Griffen: Isn't that the way it always goes?

Joe Zembas: Unfortunately, yes.

Bryan Griffen: So, when you're out there and you're looking for that big game, you're not just shooting at anything that moves. You're obviously, you're looking for something large and important. A buck that's got lots of points on it.

So for our audience, what's the big picture here? How does improving OEE translate into real performance and profitability in manufacturing?

Joe Zembas: Well, a great thing about focus on an OEE is if you think of a business and they're out there running whatever, 40% OEE. They're paying all their salaries, they're paying their utility bills, they're paying their depreciation, et cetera, et cetera, and they have their profit margin, whatever, 20%.

Every other case you make in that manufacturing plant, all those fixed costs are already paid for. So your margin on that additional 10, 20, 40% OEE that you improve, all the additional costs that you're adding on that side of the spreadsheet on the ledger is the cost of materials. So the profitability on those cases is like 80%.

I mean, and it depends, you know, business to business, but you're not paying for more heating, ventilation, and air conditioning in the room. You're not paying for more operators. They're all there. Your management staff, your HR, your legal, everyone, you're paying for them with a 40% OEE. So then when you up it and you're running another 40% more, those cases are like printing money.

Bryan Griffen: Okay. That makes a whole lot of sense. So I think, from my perspective, that a story from the field, if you will, would really help our audience connect the dots. So can you share an example from Smucker's where you tracked OEE and it turned into real world gains, kind of like, you know, finally bringing down that biggest buck of the season?

Joe Zembas: Sure. A great example from our coffee business. We had a horizontal form fill bagger, making a gusseted bottom bag for coffee.

It wasn't a complex machine. It was like eight servo axes, a bunch of cams, heaters, et cetera, et cetera, on the machine. It ran about 30, 35 bags a minute. Your standard, run of the mill horizontal bagger. It was running about 35-38% OEE when we decided to go focus on making that machine run better.

And, if you look at it from an availability standpoint, there were certain things that that machine required. It required to be shut down to splice in a role of new film and things like that. So there are certain parts of the 24-hour day we were not going to be able to go after. But the other parts, the performance issues, the quality issues we were able to go out and really address.

After about a year of working on that piece of equipment with a multifunctional team, which is a key. You know, because stereotypically, if you ask the engineer, it was a perfect machine, it's just the operations messed it up. You ask the operations, you know, engineering bought the wrong one, and quality complaints, we can't make anything right. You name it, everybody back and forth.

So the great thing is, you get everybody in the room, get everybody bought in to really making it hum, and in doing that and going through about a year's worth of effort, we got to where the one month that machine ran nine 12-hour shifts with no unplanned stops.

Compare that to a 30, 35% OEE to start with, when you have nine perfect shifts, you can put that in the W column.

Bryan Griffen: Yep, that's impressive. That sounds like a fantastic example of what an average factory can gain from improving their OEE.

So to close out our discussion today, I want to do a round of quick fire questions, if you will.

So I'm going to ask you a question, and I want you to tell us the first thing that pops into your mind, all right? All right, here we go. So question number one, if a piece of equipment has a sudden performance drop, What's the first thing you do?

Joe Zembas: Ah, well, the first thing I would do is go pull the data. What's the before and after? Try and really understand what likely root causes may come immediately to the top of the pile. Things like changes in raw materials, changes in staffing, all those kinds of things can very quickly be identified and troubleshot just by pulling the data of what's going on in that operation.

Bryan Griffen: Very good. So question number two, how can small plants get OEE benefits without a huge investment?

Joe Zembas: Well, as I mentioned, there are some devices out there for $50 to $100 that will track the very simple systems. You know, in one operation that we acquired way back in my career, we just did the novel thing that we'd done in many other plants that I'd worked at is we put a spiral bound book out on the piece of equipment and ask people to write stuff down.

So it could be as simple as, you know, writing things down. It could be as simple as a very simple tracker. Or if you've got the skill and the capability or you're willing to buy it, a little bit of PLC programming and pulling a couple of tags and dropping them into a database, you can work wonders very quickly in today's electronic world.

Bryan Griffen: It all starts with data, though, doesn't it?

Joe Zembas: Yes, it does. The point of really looking at staffing and other things is it's not just machine data. There's no machine that runs independent of materials and human interface. So it's looking at all the data, not just downtime.

Bryan Griffen: That's a fantastic point. So question number three. How can real-time monitoring lead to better decision making?

Joe Zembas: Well, real-time is really when it matters. You know, if you've got your scope on that buck, now is go time. It's the same on a piece of machinery.

You really need to be able to give the people that are on the floor around the machine, the operators, mechanics, whatever your work system looks like. You need to give them data, you know, that's current and relevant to what they're trying to do. If it's a fairly advanced piece of machinery, you could have run charts or other things displayed on the screen, or it could be as simple as those notes in the notepad of really what's going on and what's happened over the last couple hours or a couple shifts that people need to know.

Bryan Griffen: Okay. Yeah, I really like your analogy there with the having the buck in your sights. That's when you got to pull the trigger. You got to go. That's when you're going to get your buck versus looking at the camera data the next day and saying, oh the buck did pass, we just weren't looking. So I like that analogy.

So final question. If a piece of equipment in your plant Was up for an MVP award, which one would you nominate, and why?

Joe Zembas: Oh, well, there's one of my favorite stories just because it's one of those ones that, you know, it was kind of like it spins your head around. We had a multipack cartoner where we had five different production lines feeding one multipack cartoner.

I happened to be in the manufacturing plant as an engineering leader, and I was asked to support the operation by picking up responsibility to get that multipack cartoner running better, because it was running 28, 30% on any given day. I went over and got into it, and again, leveraged that multifunctional team as I spoke to, because I've found through my career, that is just the gem in how to get through these problems.

And within a week we'd identified that that cartoner was fantastic. Now you might say, "Well, geez, how can they be only putting out 28%?" Because that cartoner being fed by five different other production systems, five different production lines, was starved most of the time.

So it was being held and, just so happened to be the 80% of the time it was starved was by the same one of those five. So the real effort wasn't to work on the cartoner. The real effort was to go work on that one production line and get its results up so that you could get the right five products coming into the multipack cartoner.

So it was one of those great ones where, you know, at the end of the day, the cartoner ran really well and the system ran really well, but it started from a spin-your-head-around 180 that the cartoner is not the problem. Even though that's where management originally thought it was.

Bryan Griffen: Right, right. Oh, I love that story. That really brings to the foreground the fact that you need to understand all of the equipment in the line in order to have that overall equipment effectiveness.

So thank you for that, thanks, Joe. That was an outstanding discussion. I really appreciate you taking time out of your hunt to be with us today. I hope you find your big buck on the way out.

And to our audience, thank you for joining us today. We hope that you've enjoyed the chat with Joe Zembas and picked up some useful tips on improving efficiency with OEE.

Be sure to check out ProFoodWorld.com com for more processing tips, case studies, industry news, and upcoming events.

Don't miss out. There's a lot of practical content to explore there. Thanks again, and we'll see you next time.