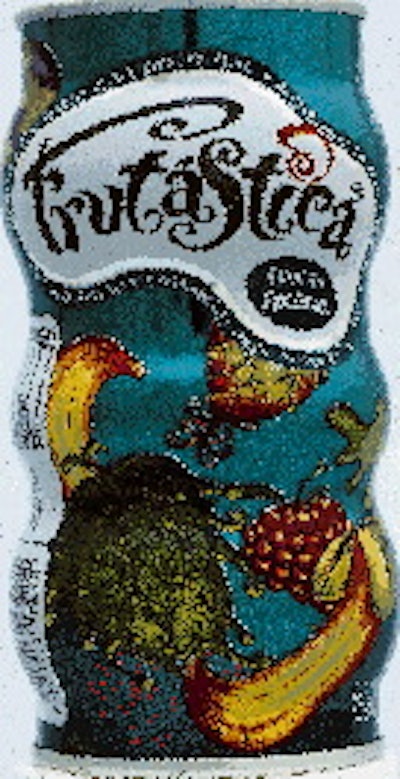

Used for its new Frutastica juice drink, the can began appearing in Mexico last October and will be available in the U.S. in the next few months.

The can is remarkable for its undulating, wavy shape. It signals consumers that this is a new breed of drink altogether, according to Boro, since it combines unusual flavors, is lightly carbonated, and contains real fruit juice. The playful shape is also designed to entice the drink's targeted demographic: young people aged 14 to 22. The 295-mL cans retail for about 3.5 pesos (42¢).

Unfortunately, Grupo Jumex declined to supply any technical details, apart from acknowledging that it makes its own cans. For some educated guesses, Packaging World turned to Heinz Grossjohann, president of Container Machinery Corp. (Kiderhook, NY), which represents can-making machinery manufacturers from Europe and the Far East.

We asked why Grupo Jumex is able to produce dramatically shaped, mass-market cans with apparent ease, while Coke's first U.S. attempt at a shaped can (see PW, Mar. '97, p. 8) displayed less prominent shaping?

The two can't be compared, according to Grossjohann. That's because shaping drawn and ironed (D&I) aluminum cans like Coke's is much more challenging than shaping a welded, non-D&I steel can like Grupo Jumex's.

"When you draw and iron the can, you thin out the sidewalls and harden them," he says. As a result, the cans lose most of their ability to stretch. In contrast, non-D&I cans are much easier to shape, since some steel or aluminum materials can be stretched up to 20%. That could explain how Grupo Jumex can produce a can with such an exaggerated shape for FrutSigmastica.

Shaping non-D&I steel cans is also cheaper than shaping D&I aluminum cans, according to Grossjohann. For his part, Grupo Jumex's Boro says the FrutSigmastica can represents only about a 5% upcharge over non-shaped cans. Grossjohann explains how this can be: "When you shape a D&I aluminum can, if you increase material usage, by, let's say 20 percent, you make the can 20 percent more expensive. With steel, if you just use a softer material, it may only be a marginal increase."

It's unclear how much the shaping equipment slows down the can-making operation. Grossjohann does say there is equipment that will shape cans at welding line speeds.

Most of the currently available shaping equipment works on the same general principle: cans are loaded onto mandrels that contain segmented dies that expand outward, forming the can into the desired shape. Since there are few suppliers of this type of equipment worldwide, Grossjohann speculates that the machine may be supplied by Oberburg Eng. (Oberburg, Switzerland), a manufacturer his firm does not represent.

He also speculates that FrutSigmastica's wild shape probably required minimal changes to the filling line, because it's steel. Unlike aluminum, steel retains much of its strength after it has been shaped, eliminating in many cases the need to make substantial changes to the filler or seamer.

On behalf of Grupo Jumex, Boro was not able to confirm or deny any of the foregoing. What he does report is that the product appears to be successful. "The product is completely different, the taste is different, and the can is completely different. And the strong point of our business is the can."