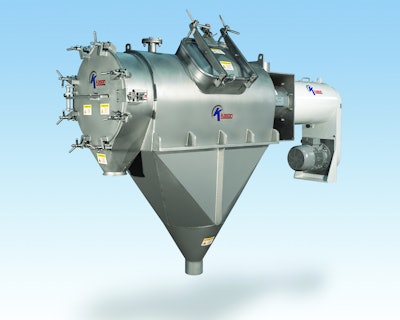

The Kason model XO-B CENTRI-SIFTER centrifugal sifter can scalp more than 100 tons per hr of dry or moist powders or granular material, and de-lump materials that tend to ball or agglomerate. It also can dewater solids-laden slurries at rates exceeding 500 gpm, depending on the application. As bulk solid material enters the inlet, a feed screw redirects it into the cylindrical sifting chamber, where rotating helical paddles accelerate the material, propelling it against and through apertures in the cylindrical screen. Available in carbon steel or 304/316 stainless steel with an industrial or sanitary finish, and with electrical systems rated to explosion-proof standards, the sifter can be configured for gravity operation or inline with positive or negative pressure pneumatic conveying systems.