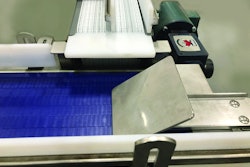

Conveying solutions are plug and play

This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

VAC-U-MAX Signature Series conveying solutions vacuum-convey powders, pellets, flakes, pastilles, dried fruit, nuts and other granular food ingredients to processing and packaging lines. Each of the five-part plug-and-play systems includes a pick-up wand, convey hose, vacuum receiver with automatic pulse filter cleaning, a vacuum producer and UL-listed controls. Available in sanitary versions, 1500 Series models achieve rates from handfuls to 1,500 lb per hr, while 3500 Series systems convey up to 3,500 lb per hr.