This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

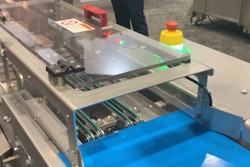

For applications that need a little extra boost in load capacity, the Dorner 2700 medium-duty conveyor has the strength to carry heavier products for a variety of industrial automation and packaging applications, including palletizers, multi-lane processing, case and tray handling, and end-of-line packaging. The unit is engineered to safely convey up to 150 lb.

The 2700 medium-duty conveyor comes in extended widths between 26 and 36 in., available in 2-in. increments. The conveyor can be wider than it is long, which enables an AMR to dock sideways, allowing more efficient, faster loading and unloading.

Features and benefits of the 2700 medium-duty conveyor include:

- V-Guided positive belt tracking for smooth, maintenance-free performance even under demanding side load applications

- Precise rack and pinion belt tensioning for fast and simple tensioning

- Larger, sealed-for-life bearings that easily handle conveyor capacity, while reducing maintenance

- 5/8-in. high speed nose bar transfer tail for precise transferring of small packages

- Engineered for applications involving multi-lane and medium part handling; transfers; accumulation; automated and manual assembly