This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

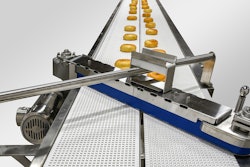

The Key Technology Zephyr horizontal-motion conveyor gently moves product with minimal bounce to protect product quality and reduce noise. The reversible Zephyr is ideal for frozen bulk foods, including potato products, fruits, vegetables, meat, and poultry, as well as dry products like potato chips/crisps, nuts, and cereals.

Zephyr’s unique motion profile slides and conveys product with no segregation or stratification, and it reduces product damage and the loss of coatings, such as seasoning, batter, and certain types of oil. The Zephyr offers up to twice the throughput of other horizontal-motion conveyors, while limiting noise to 75 decibels or less.

When integrated with pneumatic controls on the production floor, the reversible Zephyr allows processors to change direction of product flow with either the push of a button or automatically if fully integrated with the line. The reversible Zephyr can be configured to separate a single product stream to two side-by-side machines or divert a single stream to two different downstream production lines to produce different products.

Zephyr’s robust construction helps maximize sanitation, ease cleaning, and reduce maintenance. Its easy-to-maintain drive system requires no timing setup and can be located in any position below the bed to support seamless integration with other equipment in the line. With a bed width and length that can be tailored for individual customer applications, Zephyr can be equipped with a variety of options, including slide gates for scale feed distribution, a discharge to enhance multi-head weighing, or a bias to spread product when feeding downstream systems. It can also be configured with a stop-start mode for scale feeding or product distribution.

Zephyr easily accommodates varying product flow rates, maximizing the flexibility of the system to meet a broad range of user requirements. The reversible capability is available on new Zephyr conveyors and as a field upgrade for installed systems.