This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

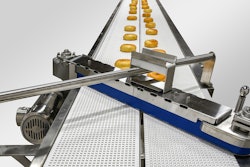

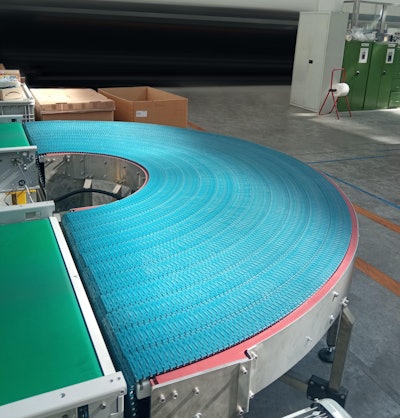

The Rexnord Curve System with a 1540 Series MatTop chain is designed for conveyor lines requiring a zero tangent 180- and/ or 90-degree curve. The system offers a 420-mm inner radius and 15-mm transfer to improve space utilization and package handling.

The Rexnord Curve System enables head-to-tail transfer of even small and light cases without the need for micro pitch conveyors, transfer modules, or plates. A consistent small nose radius across the width of the conveyor and small transfer result in a safe small gap between the system and the adjacent conveyor. This eliminates the need for roller transfer bars while providing more flexibility in container types when changing lines. Consistent angular speeds of the system’s modular belts ensure products travel through the curve without rotation.

The Curve System uses the lowest number of bearings for zero tangent curves in the industry, minimizing the need for maintenance. The drop-in solution can easily be integrated into existing conveyance systems. It uses multiple industry standard-width chain strands and can be installed by a single person. Its bevel curve retention system ensures a flat conveying surface and easy chain removal.

“The Rexnord Curve System has a cohesive design for optimal performance and ease of maintenance,” says Chad Walker, global product manager, Regal Rexnord. “The product features several industry bests, in both tightest inner radius and smallest transfer, which offer customers unprecedented benefits in both space utilization and package size handling flexibility.”