This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

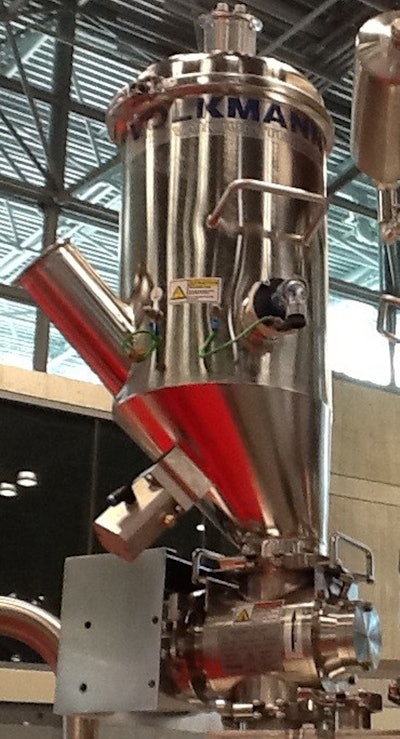

Volkmann pneumatic vacuum conveyors are available with rotary valves that have a proprietary design that allows the conveyors to meter powders, pellets, granules, and other bulk materials in a continuous flow rather than transferring materials in pulsed plugs. Suitable for feeding mixers, extruders, reactors, and a variety of continuous processes without interruption, the rotary valves create a leak-proof seal that maintains the proper pressure differential between the vacuum receiver and hose or piping while consistently discharging the material for smooth, efficient, non-stop transfer.

Typically specified as a companion with Volkmann pneumatic vacuum conveying systems, the rotary valves are manufactured from 100% stainless steel in product contact areas for sanitary processing and disassemble easily for quick cleaning. The rotary valves come in 4- and 6-in. diameters to accommodate a range of throughputs, capacities, materials, particle sizes, and other requirements and are ATEX certified as explosion-proof for use in hazardous and non-hazardous installations.