This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

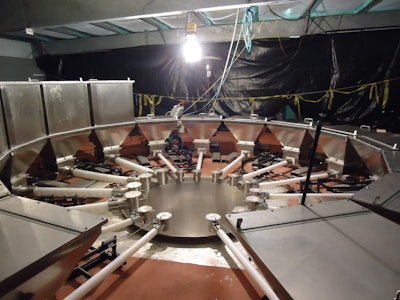

The Automated Flexible Conveyor batch-weigh system can be configured to automatically transfer, weigh, and dispense multiple materials fed from multiple locations to a common discharge location. Integrating proprietary weighing technology, PLC-based process controls, and load cells with a flexible screw conveyor, the batch-weigh system is suitable for loading a variety of powders, granules, flakes, pellets, and other bulk materials into mixers, blenders, hoppers, tanks, and containers, in preset amounts.

Eliminating the potential for over and under weighments due to human error, the batch-weigh system achieves a 99% or better batch weighing accuracy to ensure the mixture, blend, and end product meet the targeted specifications.

The batch-weigh system features a menu-oriented display with built-in recipe storage to enable a single entry level operator to consistently produce a repeatable, identical product at the push of a button. Adjustments to the recipe, such as adding, removing, and substituting ingredients, and increasing or reducing the amounts may be made on the fly from the front-facing control panel.