This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

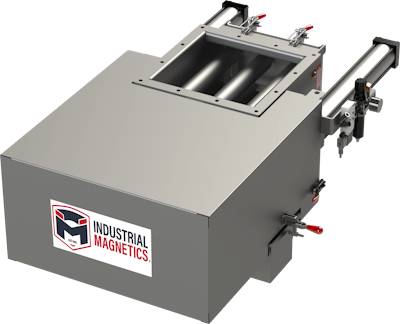

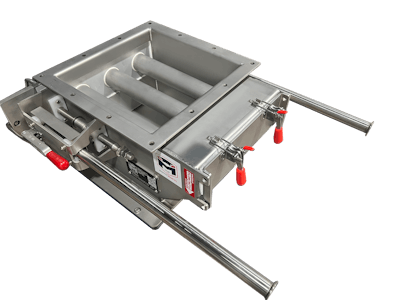

Industrial Magnetics’ Mid Tube Drawer-In-Housing (MTH) unit was developed into the company’s purification sector of products. Designed to handle even the most difficult food products, this unit excels in high-throughput applications. Some common examples of this would include, but are not limited to, cake mixes, powdered sugar, pea protein, talc, stucco, and wheat hulls.

Mid-Tube Housings incorporates 2-inch diameter rare earth magnetic tubes on 4-inch centers into our proven Drawer-In-Housing configuration. The powerful 52 MGOe Rare Earth Circuit is designed for optimum reach out and surface holding strength. This is the key to optimum ferrous metal extraction for difficult flowing products in high-flow rate applications.

IMI offers a wide range of options for this product, including custom sizes, transitions, collections pans, and so much more.