This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The Key Technology Veryx digital sorter for petfoods integrates seamlessly with Key’s material handling systems, finding and removing foreign material (FM) and products with defects.

Veryx can be configured to sort a wide range of petfoods. When installed at the end of the line, it helps ensure final product quality for kibble, chews, and treats, including dried, dehydrated, and freeze-dried products. When installed upstream near raw receiving, it inspects ingredients, such as frozen proteins and other ingredients, for wet petfoods. By detecting the color, size, shape, and/or structural properties of every object, Veryx removes plastics, glass, paper, and other FM, as well as product defects, as defined by each petfood processor.

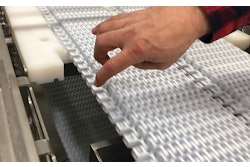

Key can integrate Veryx with a variety of it vibratory and mechanical grading solutions for transferring, scalping, size separation, fines removal, product distribution, and more. Iso-Flo, Impulse, Zephyr, and Marathon vibratory conveyors, as well as Key’s rotary separation equipment, are all suitable for petfoods, depending on the application.

Each Veryx is tailored with the optimal cameras, laser scanners, lighting, ejection system, product handling, and software to meet each customer’s specific requirements. Utilizing in-air inspection, Veryx sees all sides of the product with no blind spots. Next-generation cameras and laser scanners offer twice the resolution of previous sensor technology to find smaller FM and defects. Available in different widths, Veryx satisfies a wide range of capacity requirements.

To maximize FM and defect removal, Veryx can be equipped with Key’s proprietary Pixel Fusion technology, which combines signals from multiple cameras and laser scanners at the image pixel level to more clearly identify even the most difficult-to-detect FM and defects. Pixel Fusion helps Veryx to better identify specific FM types and enable the optional FMAlert function to send a smart alarm if a critical quality problem occurs, so quick corrective action can be taken. FMAlert also saves a time-stamped image of every critical piece of FM detected by the sorter, which helps processors document and pinpoint product quality events and trends.

Key equips every Veryx with its Discovery suite of software capabilities, which enables the sorter to collect, analyze, and share data, while continuing to sort product. By harnessing data about the sort process and about every object flowing through the sorter, Discovery can reveal patterns and trends that improve sorting and control upstream and downstream processes.

Veryx eliminates the need for manual inspection, which decreases labor costs and ensures more consistent FM and defect removal, while maximizing yields. To ease use and simplify operator training, a highly intuitive UI provides different views to users of various levels depending on their needs. Recipe-driven operation ensures customers can count on consistent performance from their Veryx sorter day in, day out. Operator qualification requirements are reduced, allowing a minimally skilled individual to become a proficient user of the system in less than 1 hr.