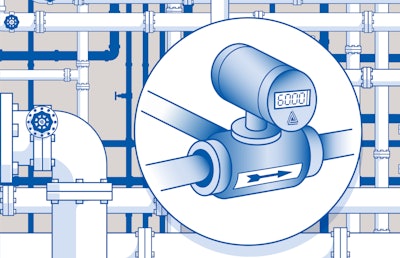

Electromagnetic flow meters, often called mag meters or magnetic-inductive flow sensors, are devices used to measure the flow rate of conductive fluids, such as water, wastewater, slurries, and certain chemicals. They use Faraday’s Law of Electromagnetic Induction, which states that a voltage is induced when a conductive fluid flows through a magnetic field. The induced voltage is directly proportional to the fluid’s velocity (higher flow rate = higher voltage; less flow = lower voltage), which allows for precise flow measurements, making electromagnetic flow meters a popular choice in various industrial applications.

A key advantage of electromagnetic flow meters is their ability to measure both clean and dirty fluids, enhancing their versatility. For example, they can accurately measure wastewater or sludge, which is often challenging for other types of flow meters. Additionally, these meters are unaffected by factors like product viscosity, density, temperature, and the presence of suspended particulates and solids, allowing them to be used effectively in different environments and industries.

How electromagnetic flow meters work (warning: it involves math)

The flow meter has two electromagnetic coils that create a magnetic field perpendicular to the direction of fluid flow inside the pipe. As the conductive fluid moves through this magnetic field, it cuts across the magnetic field lines, inducing a voltage. According to Faraday’s Law:

E = B⋅v⋅d

Where:

- E: induced voltage

- B: magnetic field strength

- v: fluid velocity

- d: distance between the electrodes

Since the magnetic field strength and distance between the electrodes are constant values in an electromagnetic flow meter, the equation can be simplified to E = K ⋅ v, where K is the constant value of the magnetic field strength x the electrode distance. Electrodes placed on opposite sides of the pipe measure the induced voltage.

Since flow rate = velocity × pipe cross-sectional area, the device can also calculate the volumetric flow rate in liters per second or cubic meters per hour and aggregate the amount of fluid that has passed through it over time. Furthermore, electromagnetic flow meters can measure bidirectional flow, which adds to their utility.

Recent advancements in technology have led to the development of electromagnetic flow meters that can measure fluids with lower conductivity levels (typically >5 microsiemens (µS) per cm), broadening the types of fluids that can be accurately assessed. However, these meters are not effective for non-conductive fluids like oils or deionized water.

Advantages of electromagnetic flow meters

A significant advantage of electromagnetic flow meters is that they have no moving parts, resulting in lower maintenance costs and a longer service life than mechanical flow meters. They also offer high accuracy rates, achieving measurements with an accuracy of up to ±0.5% of the flow rate, which is superior to many other flow measurement technologies. This precision is particularly valuable when accurate fluid measurement is essential.

Moreover, electromagnetic flow meters experience minimal pressure loss during fluid measurement, enhancing the overall operational efficiency of the systems they are integrated into. Their ability to measure flow in both directions provides significant operational flexibility, making them suitable for a wide range of applications. With a favorable turndown ratio of approximately 40:1, these meters can effectively measure a diverse range of flow rates, accommodating various operational demands.

Calibration, maintenance, and troubleshooting

Regular calibration is crucial to ensure accurate measurements. This process typically uses water to validate the K factor (magnetic field strength x the electrode distance), which can be applied to other conductive liquids. Maintenance tasks also include ensuring proper grounding to prevent zero shifts and addressing potential issues such as air entrainment or electrode coating that can affect performance.

Installation guidelines for electromagnetic flow meters underscore the importance of maintaining a full pipe and adhering to specific upstream and downstream straight pipe requirements to enhance measurement accuracy. Periodic verification checks are essential to confirm the functionality and accuracy of the flow meters over time. Users should also consider environmental factors, such as temperature fluctuations and electromagnetic interference, which may impact performance.

Applications in food and beverage processing and other industries

Electromagnetic flow meters play a crucial role in the food and beverage industry by providing accurate, non-intrusive flow measurements for liquids such as milk, juices, beer, syrups, and other conductive fluids. Since they have no moving parts, they minimize the risk of contamination and ensure hygienic operation, making them ideal for scenarios requiring strict sanitation standards. Their smooth construction allows for easy cleaning and integration with CIP/SIP systems, ensuring no residue or bacteria accumulate. Additionally, electromagnetic flow meters provide real-time monitoring of liquid flow rates, helping manufacturers optimize ingredient mixing, reduce waste, and maintain consistency in product quality. Their ability to measure a wide range of viscosities and temperatures makes them highly versatile for processes like dosing, batching, and filling operations.

Electromagnetic flow sensors have broad usage across industrial applications as well. Their ability to handle slurries and highly corrosive fluids without obstruction makes them ideal for many scenarios, including water treatment, chemical processing, and wastewater management. As technology evolves, the adoption of flow sensors in agriculture is also increasing, particularly for measuring irrigation flows and monitoring water usage. Their use in cooling water systems further emphasizes their versatility, where they help monitor flow rates to improve energy efficiency.

Factors to consider when purchasing

Not all electromagnetic flow meters are built the same. Smoothness is vital for washdown processes in hygienic processes like food and beverage applications. These processes require areas that wash down very cleanly, drain away freely, and do not trap buildup or bacteria. Washdown processes are very aggressive and often involve high-pressure hoses and harsh chemicals. It’s important to recognize the flow meter's IP rating to understand its resistance to particulate and moisture penetration.

Thermal stability is also relevant for many operations that experience wide swings in temperature (internal or external) over time. For example, if a company pasteurizes milk at elevated temperatures but also works with chilled elements slightly above freezing, then thermal shock/expansion and moisture wicking are potential issues. Filling the core with a thermal potting material can significantly reduce both problems.

Meter size and compatibility are also important considerations. Since many plant operations have been added over time, various systems and manufacturers are often in place. Therefore, the length of flow tubes compared to available fitment points must be considered. Can a meter be a drop-in replacement, or are custom-length tubes available?

Communication methods are also paramount. How well will the proposed electromagnetic flow meter integrate with your existing systems, and what communication methods do they support? (e.g., IO-Link, Ethernet, analog)

Several attributes should be considered before buying your next electromagnetic flow meter, not only of the device but the manufacturer as well. Comparing the capabilities of competitive products is—as always—crucial, but consider comparing the capabilities of the manufacturers, too. For instance, are they a proven partner to food, beverage, and ingredient professionals seeking to improve uptime and performance? Do they embody the advancement of industry efficiency, sustainability, and integrity with quality, reliable components, and comprehensive client care (including warranty and technical support)? Looking at products and manufacturers holistically will help you make a successful, problem-free choice.