This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

All-Fill’s Eco-Capper was designed to give customers an economical offering when a capping machine is needed. The standard dual-station chuck capper can be overkill for customers, making a straightforward single-station chuck capper a more practical choice, especially when rates are not their main concern. The Eco-Capper can achieve rates of up to 50 cpm (application dependent) and pairs seamlessly with our single-head automatic filling machines and labelers.

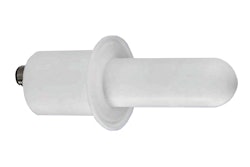

The Eco-Capper features an integrated, 8-foot indexing conveyor, supported by stainless steel rounded legs for easy cleaning. The cap elevator is a 4.5-cubic-foot-capacity hopper that efficiently transports caps through a cap trap and into the chuck placing and torquing head. The Eco-Capper features a 7-inch Weintek color HMI touchscreen for user interface and operator controls and can save up to 100 recipes/programs.

All-Fill can provide customers with everything needed for a full production line, accommodating various production rates.