This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

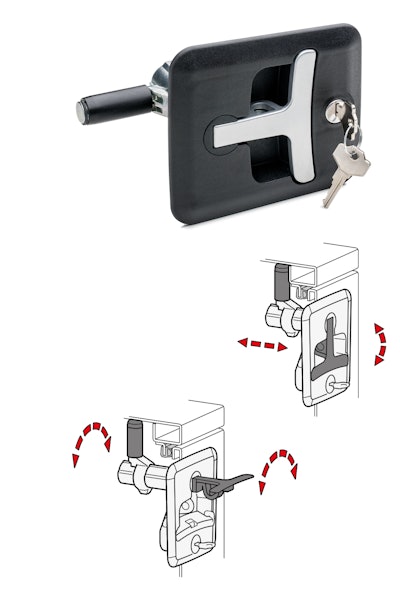

Intended to hold doors, covers, and hatches closed, the JW Winco compression latch is operated in two steps with an ergonomic, powder-coated T-handle. When the handle is folded in or out, a 5-mm stroke is initiated on the rotating Lift and Turn EN 5630 compression latch to generate the required pressure against a door seal. In the folded-out position, the handle can be turned to the left or right, moving the rotating latch 90 deg behind the cover or door, allowing it to be opened. The rotating latch can be adjusted for frames between 13- and 75-mm thick, depending on the application. It has a polyamide closure housing with a permanently integrated silicone seal for protection class IP65.

PACK EXPO Connects – November 9-13. Now more than ever, packaging and processing professionals need solutions for a rapidly changing world. The power of the PACK EXPO brand to deliver the decision makers you need to reach. Attendee registration opens September 15. Be notified when the site goes live by clicking here.