This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Given the recent challenges of carbon dioxide (CO2) availability, Messer is helping processors across the country convert to liquid nitrogen (LIN), where feasible, and thus, improve the security of their cryogen supply. Messer’s bottom-injection chilling systems utilize either LIN or CO2 as the cryogen to chill ground meat, poultry, seafood products, and even bakery dough, with cutting-edge efficiency.

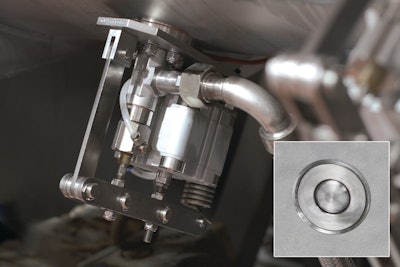

The patented, hygienic Kryojector injector, controlled by the proprietary Messer universal bottom injection control panel (UBIP) can improve food safety, avoid nozzle plugging, deliver consistent batch-to-batch chilling, and reduce blender cycle times.

The hygienically designed Kryojector injector seals flush against the blender wall, reducing debris collection and particle entrapment. When the UBIP opens the Kryojector nozzle, it injects a defined amount of cryogen directly into the product mass. The cryogen evaporates or sublimes in contact with the product, absorbing the heat from it, and the cold gas then continues to cool the product as it passes through the mixer, blender, or kettle from the bottom to top.

The Kryojector bottom injection chilling system (which includes the UBIP) requires minimal space and minimal cleaning. It cools the product directly and quickly, reducing phase separation, microorganism growth, product stress, and aroma losses, resulting in high product quality. The high-capacity bottom injection system has been designed to efficiently use the cryogen and reduce the freezing of product near the cryogen injection point, which has historically been problematic for competing systems. It can be installed in new process equipment or retrofitted into an existing system.

In addition to proteins and bakery dough, the Kryojector injector is suitable for blender/mixer chilling of not-yet-formed vegetable products, sauces, soups, purées, baby foods, paste, and pulp products.