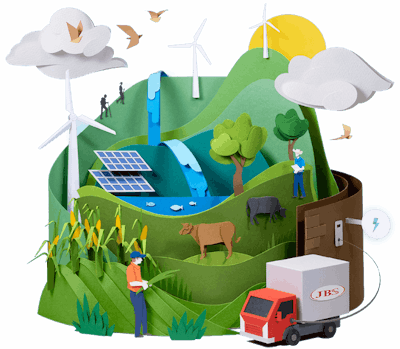

JBS is installing biodigesters at nine Friboi plants in Brazil to convert methane gas emitted in their operations into biogas, a renewable, clean energy source. The installations are projected to reduce the business’s scope 1 emissions by 65%, representing a reduction of 24.6% across all JBS activities in the country.

The biogas will be used for steam production in the units’ boilers, as a source of electricity generation, and as a fuel for the fleet of JBS Transportadora. The largest project of its kind in Brazil’s protein industry, the biodigester system installation is expected to be complete later this summer.

Fourteen JBS plants in the U.S. and Canada already have biodigester systems producing 190,000 m³/d of biogas, which fuels boilers, is used to produce electricity at the company’s units, and is sold to gas companies. The projects in the U.S. and Canada have reduced by 20% the external demand for natural gas, allowing JBS to reduce greenhouse gases by 650,000 tons each year.

| JBS USA Names New CEO |

“In line with our circular economy actions, the biodigesters will reduce our methane emissions and initiate the production of clean and renewable energy,” says Maurício Bauer, corporate sustainability officer of JBS Brazil. “This project strengthens our view that agribusiness is part of the solution for addressing the challenges of climate change that the world is facing.”

JBS also is investing in biogas projects in Australia, in partnership with the company Energy360, with the potential to eliminate 60,000 tons of CO2 emissions, with annual savings of approximately $1.3 million in natural gas expenses.