Ensuring the highest standards of food safety is important throughout the food and beverage industry. But that becomes even more paramount in fresh produce, where there is no kill step—no cooking or sterilization along the way—to mitigate contaminant risks. Contaminated produce has been responsible for many foodborne illnesses around the world, and the pressure is on producers to focus even more on hygiene to minimize exposure to health hazards.

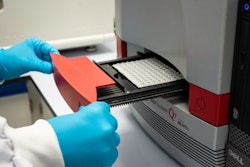

In a project funded by the German Federal Ministry of Food and Agriculture (BMEL), several organizations worked together to test a newly developed Hewa washing machine from Kronen in combination with a plasma washing process in an industrial setting. Over the past 12 months, partners in the SPLASH project have been testing the washing process for fresh-cut lettuce using non-thermal plasma technology. Plasma-treated wash water (PTW) is used in a washing machine adapted for this purpose to reduce the risk of packaged cut salads being contaminated with microorganisms.

Kronen partnered with Gartenfrisch Jung at its fresh produce facility to prove the effectiveness of the PTW on baby leaf lettuce and other types of lettuce in the Hewa washing machine. The tests examined the disinfection efficiency in the wash water and on the treated products, resource savings compared to other disinfection methods, and the optimization of the products’ suitability for storage and transport.

The results were promising. Compared to washing with normal tap water, the plasma-treated water improved the antimicrobial effect while also producing no negative effects on the product. The project achieved its objective of developing a resource-conserving washing process using non-thermal plasma technology for disinfecting cut lettuce as gently as possible. The hygienization of the lettuce increases consumer safety by avoiding premature spoilage.

In addition to Kronen and Gartenfrisch Jung, the SPLASH project draws on expertise from the Leibniz Institute for Agricultural Engineering and Bioeconomy (ATB Potsdam) and the Leibniz Institute for Plasma Research and Technology (INP Greifswald) to develop innovative, practical solutions to improve food safety.

With the test phase concluded successfully, the partners will continue to work together to scale the solution to meet industrial requirements.