The Centers for Disease Control and Prevention (CDC) released guidance for meat and poultry processing workers and employers—including those involved in beef, pork, and poultry operations. CDC clearly that this new guidance supplement does not replace general guidance at these web sites:

Workers involved in meat and poultry processing are not exposed to SARS-CoV-2 through the meat products they handle. However, their work environments—processing lines and other areas in busy plants where they have close contact with coworkers and supervisors—may contribute substantially to their potential exposures. Distinctive factors that affect workers’ risk for exposure to SARS-CoV-2 in meat and poultry processing workplaces include:

- Distance between workers – Meat and poultry processing workers often work close to one another on processing lines. Workers may also be near one another at other times, such as when clocking in or out, during breaks, or in locker/changing rooms.

- Duration of contact – Meat and poultry processing workers often have prolonged closeness to coworkers (for 10-12 hours per shift). Continued contact with potentially infectious individuals increases the risk of SARS-CoV-2 transmission.

- Type of contact – Meat and poultry processing workers may be exposed to the infectious virus through respiratory droplets in the air – for example, when workers in the plant who have the virus cough or sneeze. It is also possible that exposure could occur from contact with contaminated surfaces or objects, such as tools, workstations, or break room tables. Shared spaces such as break rooms, locker rooms, and entrances/exits to the facility may contribute to their risk.

- Other distinctive factors that may increase risk among these workers include:

- A common practice at some workplaces of sharing transportation such as ride-share vans or shuttle vehicles, car-pools, and public transportation.

- Frequent contact with fellow workers in community settings in areas where there is ongoing community transmission.

According to the supplemental guidelines, a qualified workplace coordinator should be identified who will be responsible for COVID-19 assessment and control planning. All workers in the facility should know how to contact the coordinator with any COVID-19 concerns. Infection control and occupational safety and health plans should apply to anyone entering or working in the plant (e.g., all facility workers, contractors, and others).

Facility management should reach out to state and/or local public health officials and occupational safety and health professionals and establish ongoing communications to make sure they are getting relevant and up-to-date information concerning COVID-19. The workplace coordinators and management should also be aware of and follow all applicable federal regulations and public health agency guidelines. Worksite assessments to identify COVID-19 risks and prevention strategies should be done periodically as part of sound occupational health and public health practice. As part of these assessments, facilities should consider the appropriate role for testing and workplace contact tracing (identifying person-to-person spread) of COVID-19-positive workers in a worksite risk assessment, following available CDC guidance.

Further controls

CDC says worker infection prevention recommendations are based on an approach known as the hierarchy of controls. This approach groups actions by their effectiveness in reducing or removing hazards. In most cases, the preferred approach is to eliminate a hazard or processes; install engineering controls; and implement appropriate cleaning, sanitation, and disinfection practices to reduce exposure or shield workers. Administrative controls are also an important part of an approach to prevention in these workplaces.

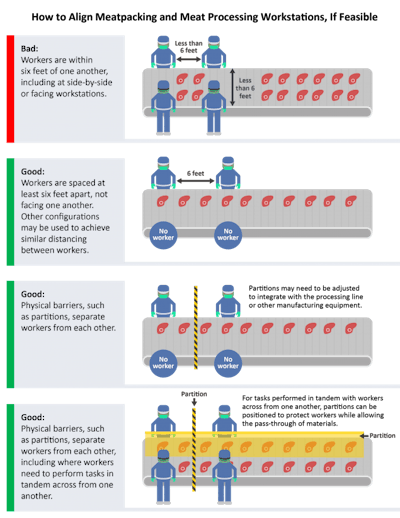

The agency says meat and poultry processors should configure communal work environments so that workers are spaced at least six feet apart, if possible. Current information about the asymptomatic spread of SARS-CoV-2 supports the need for social distancing and other protective measures within a meat and poultry processing work environment. Changes in production practices may be necessary in order to maintain appropriate distances among workers.

Modify the alignment of workstations, including along processing lines, if feasible, so that workers are at least six feet apart in all directions (e.g., side-to-side and when facing one another), when possible. Ideally, modify the alignment of workstations so that workers do not face one another. Consider using markings and signs to remind workers to maintain their location at their station away from each other and practice social distancing on breaks.

Use physical barriers, such as strip curtains, plexiglass or similar materials, or other impermeable dividers or partitions, to separate meat and poultry processing workers from each other, if feasible.

Facilities should consider consulting with a heating, ventilation, and air conditioning engineer to ensure adequate ventilation in work areas to help minimize workers’ potential exposures.

If fans such as pedestal fans or hard mounted fans are used in the facility, take steps to minimize air from fans blowing from one worker directly at another worker. Personal cooling fans should be removed from the workplace to reduce the potential spread of any airborne or aerosolized viruses. If fans are removed, employers should remain aware of, and take steps to prevent, heat hazards.

Place handwashing stations or hand sanitizers with at least 60% alcohol in multiple locations to encourage hand hygiene. If possible, choose hand sanitizer stations that are touch-free. See OSHA’s Sanitation Standard (29 CFR 1910.141external icon), which requires employers to provide handwashing facilities for workers.

Add additional clock in/out stations, if possible, that are spaced apart, to reduce crowding in these areas. Consider alternatives such as touch-free methods or staggering times for workers to clock in/out.

Remove or rearrange chairs and tables, or add partitions to tables, in break rooms and other areas workers may frequent to increase worker separation. Identify alternative areas to accommodate overflow volume such as training and conference rooms, or using outside tents for break and lunch areas.

Administrative Controls

According to CDC, employers should do the following to promote social distancing:

- Educate and train workers and supervisors about how they can reduce the spread of COVID-19.

- Encourage single-file movement with a six-foot distance between each worker through the facility, where possible.

- Designate workers to monitor and facilitate distancing on processing floor lines.

- Stagger break times or provide temporary break areas and restrooms to avoid groups of workers during breaks. Workers should maintain at least six feet of distance from others at all times, including on breaks.

- Stagger workers’ arrival and departure times to avoid congregations of workers in parking areas, locker rooms, and near time clocks.

- Provide visual cues (e.g., floor markings, signs) as a reminder to workers to maintain social distancing.

- Encourage workers to avoid carpooling to and from work, if possible.

- If carpooling or using company shuttle vehicles is a necessity for workers, the following control practices should be used:

- Limit the number of people per vehicle as much as possible. This may mean using more vehicles.

- Encourage employees to maintain social distancing as much as possible.

- Encourage employees to use hand hygiene before entering the vehicle and when arriving at the destination.

- Encourage employees in a shared van or car space to wear cloth masks.

- Clean and disinfect commonly touched surfaces after each carpool or shuttle trip (e.g., door handles, handrails, seatbelt buckles).

- Encourage employees to follow coughing and sneezing pdf icon etiquette when in the vehicle.

Employers may determine that modifying processing or production lines, shifts, and staggering workers across shifts would help to maintain overall meat and poultry processing capacity while measures to minimize exposure to SARS-CoV-2 are in place. For example, a plant that normally operates on one daytime shift may be able to split workers into two or three shifts throughout a 24-hour period. In meat and poultry processing plants, one shift may need to be reserved for cleaning and sanitization.

Consider cohorting (grouping together) workers. This can increase the effectiveness of altering the plant’s normal shift schedules by making sure that groups of workers are always assigned to the same shifts with the same coworkers. Cohorting may reduce the spread of workplace SARS-CoV-2 transmission by minimizing the number of different individuals who come into close contact with each other over the course of a week. Cohorting may also reduce the number of workers quarantined because of exposure to the virus.

Establish a system for employees to alert their supervisors if they are experiencing signs or symptoms of COVID-19 or if they have had recent close contact with a suspected or confirmed COVID-19 case.

Provide workers access to soap, clean running water, and single use paper towels for handwashing.

- Provide alcohol-based hand sanitizers containing at least 60% alcohol if soap and water are not immediately available.

- Place hand sanitizers in multiple locations to encourage hand hygiene. If possible, choose hand sanitizer stations that are touch-free.

- Consider other workplace programs to promote personal hygiene, such as:

-- building additional short breaks into staff schedules to increase how often staff can wash their hands with soap and water or use hand sanitizers with at least 60% alcohol;

-- providing tissues and no-touch trash receptacles for workers to use; and

-- educating workers that cigarettes and smokeless tobacco use can lead to increased contact between potentially contaminated hands and their mouth, and that avoiding these products may reduce their risk of infection.

Workers should be educated to avoid touching their faces, including their eyes, noses, and mouths, particularly until after they have thoroughly washed their hands upon completing work and/or removing personal protective equipment (PPE).

Further information on this subject can be found at https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/meat-poultry-processing-workers-employers.html

More links from CDC:

· Meat and Poultry Processing Facilities: Key Strategies to Prevent COVID-19 Infection among Employees pdf icon[1 page] (alternate language links)

· Meat and Poultry Processing Employees: Things you can do at work and at home to protect from COVID-19 pdf icon[2 pages] (alternate language links)

Other articles you may like:

Flowers Foods Temporarily Closes Bakery Due to Pandemic

COVID-19 Interview: Hershey Unwraps Its Supplier Access Strategy

Sales Spike for HPP Products during COVID-19 Pandemic