According to Sports Psychology Today, being in the zone is a state of supreme focus that helps athletes in all sports perform at their peak potential. This widely accepted view for athletes is equally applicable to the food and beverage industry.

A recent FSO Institute survey on technology in food and beverage manufacturing supports this notion. This survey sought to identify the correlation between a company’s level of technological maturity and the technology adoption rate of its users.

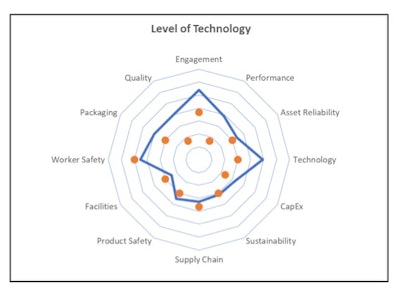

As you see in the charts , a company can compare its results to the FSO industry average for each of the 12 Dimensions of Manufacturing Health. This data can be useful for developing appropriate improvement plans.

A few observations of the FSO industry average include:

- The level of technology in worker safety, product safety, and manufacturing performance reflects the reported investments in recent years.

- The use of the technology tools provided to the workforce generally reflects an alignment to the investments.

- The upside opportunity for our industry is that most dimensions recorded to be midway on the scale.

Achieving the desired state of being in the zone requires a significant balancing act of new technology investments with the worker skills required to use that technology. While the latest technology investments promise greater productivity and effectiveness, the adoption rate of technology relies on a workforce that is skilled enough to at least manage, let alone be aligned, with its predictive capabilities.

12 Dimensions of Manufacturing Health

To enable an entirely new perspective, consider how a company employs technology through the lens of FSO’s 12 Dimensions of Manufacturing Health. What follows are insights from industry leaders, sharing how they are using technology to accelerate performance at their companies.

1. Manufacturing Performance Dimension

FSO Institute: How are you using technology to manage production schedules and improve throughput performance?

As leaders, we are obligated to enable our people and, as a result, our teams, with the capability to take true and meaningful action. Along with supporting the development of everyone’s skills, we must enable our teams with the authority to make decisions and address opportunities. Unfortunately, the combination of a comprehensive set of skills combined with the ability to make decisions is not enough. To make a meaningful impact on the organization, our teams must also have the resources to take action. The resources of today are centered in technology—technology in the form of tools, data, and analytics. Technology is the great enabler, accelerating results and cementing sustainment, when [it is] placed on a solid foundation of empowered and skilled teams.

—Greg Flickinger, SVP Operations & Supply Chain, Green Thumb Industries

2. Quality Dimension

FSO Institute: How are you using technology in your quality functions to manage and verify specification compliance?

IAF continues to refine and improve production to specification through technology. Recent additions of benchtop and production tools have driven our product quality to a new level. The introduction of a desktop refractometer in the production area has replaced handheld units to measure Brix, a key processing parameter, to a very precise and repeatable level. In addition, the routine use of a titrator to measure moisture percentages in all our products and the introduction of a water activity meter have improved our post-production quality checks and provide feedback for process improvements. In 2021, IAF plans to add a tensiometer to our sensory protocol for gummies to accurately measure mouthfeel in conjunction with actual taste and texture sampling.

—Scott Spencer, President and COO, Island Abbey Food Science

3. Workforce Engagement Dimension

FSO Institute: How do you accelerate the adoption and use of new technology?

Adoption of technology requires workforce engagement. No project big or small happens without an engaged workforce, especially when it comes to technology. Some studies show a 60% failure rate when placing technology without an engaged workforce. If the end users are not well trained and do not understand the why behind the automation you have added to their day, they will simply revert to the way of doing work that they know. The company ends up spending time and money with no real benefit, because the technology will not get used.

—Bob Gates, P.E., Sr. Director, GE Digital

4. Technology Dimension

FSO Institute: What observations can you share regarding the roles of OT and IT, and how are they changing?

I believe that OT and IT will be nondistinctions in a decade, as the two worlds continue to merge. For example, years ago, when you were developing a maintenance program, you instructed the owner to look at the ‘odometer’ and determine what PMs were appropriate to perform. You did the work of creating the maintenance plan in an IT system, because that’s where you could transcribe your thoughts and communicate them to others. The OT system tracked the odometer, but only communicated it or visualized it locally. With the convergence of the technologies with the OT and IT worlds, we continue to get more efficient, so that today, the machine communicates the ‘odometer’ to the maintenance planning system, and the maintenance system pushes the information to do the maintenance [parts, procedures, diagrams, etc.] to the plant floor. As the convergence of technologies [Ethernet communication, database management, switches, routers, and security] continues, the distinction of the two separate worlds will continue to disappear. It will become a distinction without a difference.

—Joe Zembas, Sr. Manager, Reliability Engineering, J.M. Smucker

5. Asset Reliability Dimension

FSO Institute: How are you using technology to automate the reporting of critical asset reliability issues in your plants?

Using solid data collected from the operational conditions on an asset or set of connected assets to analyze opportunities allows us to make data-based decisions, which lead to high efficiencies and profitability. Our objective for each plant is to assemble a standardized technology package, which can collect the data from the plant floor network, aggregate the data for isolating key issues, engage the team to conduct root cause analysis, implement the corrective actions and track results, and report the outcomes into our care strategy network, so it can be shared across all plants.

—Mark Hanley, CMRP, Sr. Corporate Asset Reliability Manager, Land O’Lakes

6. Supply Chain Dimension

FSO Institute: How are you using technology to inform those in the supply chain of replenishment requirements?

We provide manufacturers with the ability to connect their supply chain end to end by leveraging data and analytics that enable visibility and data-driven decision-making. We use state-of-the-art technology and science to provide better planning and execution from demand forecasting, network, and inventory optimization to scheduling solutions that incorporate production and logistical constraints and rewards.

—Dayana Cope, Director, Simulation and Data Science Practice, Engineering USA

7. Product Safety Dimension

FSO Institute: How are you using technology to enable your teams to do root cause tracking on product safety?

At Blommer Chocolate, we have moved the production floor paperwork to an electronic database. Operators use a tablet to enter this data real time. When a critical result is outside criteria limits, an immediate alert is sent via text, email, and even to the monitors around the plant, to signal attention is needed now. A team converges on the location to assess what just happened and can take instant steps to address it.

—John Hilker, Director of Manufacturing, Blommer Chocolate

8. Worker Safety Dimension

We use EHS [environmental, health, and safety] software technology to track and trend performance companywide. We leverage that information to further focus on enhancements made to our sites that will decrease the possibility of incidents. As we move forward, we are looking at predictive-based safety analytics and wearable technology to help us better manage EHS and ergonomic compliance, in light of the COVID-19 pandemic.FSO Institute: How are you using technology to manage and report on worker safety compliance?

—Xavier Aguilera, Director of Corporate EHS, Bumble Bee Seafoods

9. Packaging Dimension

FSO Institute: From a technology provider perspective, how are CPGs using technology in packaging and new product introductions?

Timely product introduction means first to market and addressing product cost erosions. CPG customers are utilizing automation to help their teams standardize new workflows for product setup and changeovers, allow faster time to market, and provide delivery to customer shelves in less time. When issues do occur, CPG companies are using the more timely and accurate reporting of the key metrics most critical to their operations. With this drilled-down ability, they are eliminating repeatable issues and developing more reliable supply for their customers.

—Bob Gates, P.E., Sr. Director, GE Digital

10. CapEx and Facilities Dimension

FSO Institute: How are you using technology to enhance communication during capital projects?

After creating an expectation about a virtual FAT during preliminary discussions with an OEM, we write it into the purchase order. Before fabrication is complete, we create a list of items to be tested or demonstrated, such as pictures, dimensions, HMI screens, interlocks, induced failure/recovery, video clips of important machine actions, machine guarding, and hygienic design. All of this is uploaded to the cloud, so it can be reviewed in advance. Then, we have the virtual FAT by Zoom, and it goes very quickly; outstanding items are added to a punch list.

—David Drum, Global Engineering, Kellogg

11. Sustainability Dimension

FSO Institute: How are you using technology to facilitate the automation of sustainability reports?

Technology for gathering sustainability data has advanced tremendously over the past few years. Automation and cloud solutions have made the collection and analysis of accurate data less challenging, allowing [us] time to work on advancing environmental progress.

—Amber Brovak, Sr. Manager, Global Safety Operations, Church & Dwight

12. Manufacturing Performance Dimension

FSO Institute: From a technology provider perspective, how are CPGs using technology to manage production schedules and improve throughput performance?

We utilize data and technology to help manufacturers become less reactive and more predictive to how their systems perform. By leveraging descriptive, predictive, and prescriptive analytics, we give manufacturers the tools they need to understand and manage their performance in real time. Using machine learning technology, we help them predict yield and quality, while providing indications of how they should intervene to make sure that their performance is within an acceptable standard. In addition, by leveraging reinforcement learning and discrete event simulation, we enable manufacturers to implement intelligent, effective production scheduling agents that can make scheduling decisions autonomously with the objective of maximizing a reward function.

—Dayana Cope, Director, Simulation and Data Science Practice, Engineering USA

Being in the zone means being in balance with your level of technology investment and all the people and teams using the technology.

Think of your favorite athlete. What is his or her journey to prepare for the zone, perform while in it, and do it repeatedly? It is a journey, just as it is for food manufacturers. To begin your journey of getting into the zone, see the free technology survey for food and beverage manufacturers at www.pfwgo.to/FSOSurveys.

The Processing Zone Returns to PACK EXPO

As a direct response to industry demands, The Processing Zone returns to PACK EXPO Las Vegas and Healthcare Packaging EXPO (Sept. 27-29, 2021, Las Vegas Convention Center). The show will showcase front-of-line solutions from food processing/systems, food safety, engineering, design and construction services and more, according to show producer, PMMI, The Association for Packaging and Processing Technologies. It will also offer targeted education via its processing-dedicated Innovation Stage.

Attendee registration opens in May. In the meantime, visit packexpolasvegas.com for more information.