When it comes to dairy processing, it’s not what you know that matters as much as who you know.

That’s evident in PMMI Business Intelligence’s “2023 Dairy Industry Report: Innovation, Adaptation, Transformation.” Over half (63%) of dairy processors claim to outsource some services in a survey conducted for the report.

Less than a fifth (19%) of dairy producers say they don’t outsource at all, and a similar amount (18%) say they aren’t sure.

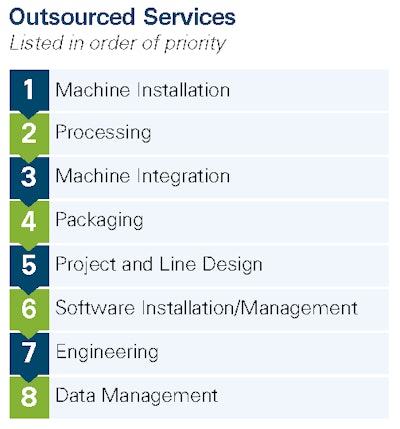

Many dairy producers note they outsource several technical aspects of their business, especially tasks related to designing, installing, and commissioning new additions to their facility and portfolio.

The most popular types of services for outsourcing include machine installation, processing, machine integration, and packaging. Machine installation is the highest priority service to outsource.PMMI Business Intelligence: 2023 Dairy Industry Report: Innovation, Adaptation, Transformation

Machine installation is the highest priority service to outsource.PMMI Business Intelligence: 2023 Dairy Industry Report: Innovation, Adaptation, Transformation

A lack of capacity is a main driver of outsourcing, according to a senior vice president and product science expert, who says, “There is simply not enough aseptic production capacity right now to support extended shelf-life product innovation – even the contract packagers are all booked.”

Project and line design and engineering are also top contenders for outsourcing.

“We have looked at ways to use more external engineering as the labor market continues to tighten,” says a principal packaging system design engineer at a global food company. “We need a company that does it all – not necessarily just our dairy portfolio manufacturing, but all of our products.”

The software side of the equation can also be outsourced, with software installation/management and data management being the most popular.

One industry expert in food engineering notes the popularity of offsite data storage, saying, “Some dairy plants are storing recipe data offsite to share with all plants around the world – so data safety and security is key since food manufacturing continues to experience cyberattacks.”

OEMs and Suppliers to Support Improvements

Dairy producers also identified wanting more knowledgeable technicians as an important need from OEMs and suppliers.

OEMs and suppliers have an essential role to play in helping dairy operations expand and improve by ensuring their technicians and consultants are true experts in the field.

OEMs and suppliers can take this a step further by proactively identifying where dairy producers could improve their operations and suggesting executable projects to realize those improvements.

Those OEMs and suppliers that can provide consistent, proactive expert assistance will be well-positioned to forge new client relationships and grow existing ones.

SOURCE: PMMI Business Intelligence, 2023 Dairy Industry Report: Innovation, Adaptation, Transformation

Download the FREE executive summary below.