This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

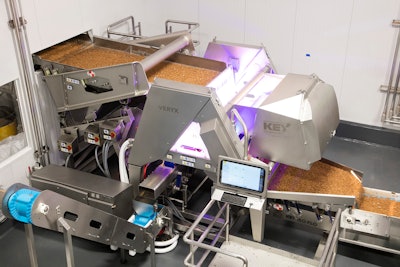

Key Technology’s VERYX digital sorter (show) is designed to find and remove foreign material (FM) and user-specified defects to protect food safety and ensure product quality while virtually eliminating false rejects and reducing labor requirements. Integrating seamlessly with Key’s specialized material handling systems, VERYX can be configured to sort fresh, dried and frozen fruits and vegetables, potato products, nuts, confectioneries, pet foods and more. Key Discovery™ software collects, analyzes and shares data to reveal patterns and trends that improve sorting and help control upstream and downstream processes.

Achieving higher capacities than other horizontal-motion conveyors, Key’s Zephyr gently moves product with minimal bounce to protect product quality and reduce noise. Ideal for processing and packaging lines handling frozen foods as well as dry products like potato chips/crisps, nuts and cereals, Zephyr’s unique motion profile slides and conveys product with no segregation or stratification and reduces product damage and loss of coatings such as seasoning and batter. An optional reversible configuration allows customers to flow product in either direction, maximizing line versatility.

Also on display was Key’s vision inspection systems that include OCULUS sorters for whole potatoes, Optyx® sorters for potato chips/crisps, and ADR® automatic defect removal systems for potato strips. Key’s Iso-Flo®, Impulse®, Marathon® and Zephyr vibratory conveyors, as well as their rotary size graders and other mechanical solutions, are ideal for a variety of applications throughout processing and packaging lines.