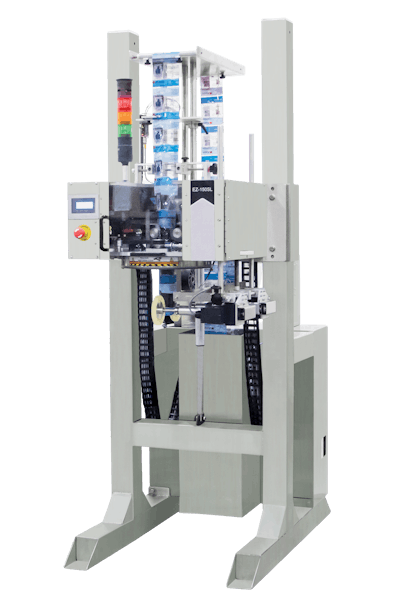

It features a stainless steel frame for long service life and the latest in servo control for fast, accurate, and trouble-free film feeding and cutting. Axon’s axial knife mechanism ensures long blade life for low cost of ownership. A color touchscreen human machine interface (HMI) makes operation easy and intuitive. This HMI was designed for today’s diverse workforce – a generation comfortable with on-screen navigation. A video of the unit is available on the Axon website.

Customers may use such films as PVC, PETG, OPS, and PLA. For the EZ-150SL, Axon designed the ThermoFlow heat tunnel. ThermoFlow is an innovative, compact, self-contained shrink tunnel that features a 15-PSI low pressure steam generator and condensate collection system. Because it is low pressure, packaging operations do not need special licensing or certifications that are required for high pressure boilers.