This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

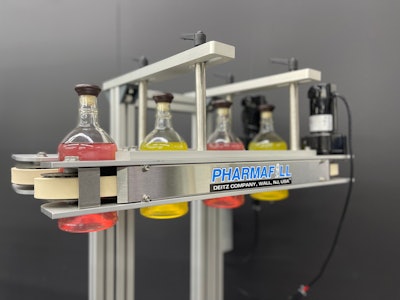

The Deitz Pharmafill BCV1 bottomless conveyor features a proprietary hugger belt design that quickly adjusts in width, with no tools, to accommodate a wide range of bottle sizes. Allowing the distance between the two hugger belts to be changed in seconds from as wide as 6.25 in. to as narrow as 0 in., the bottomless conveyor enables nutrition, pharmaceutical, and other bottling, manufacturing, and co-packing companies to transfer multiple products and/or sizes using the same conveyor.

During changeovers, an operator simply rotates hand cranks to switch from powdered supplement tubs, bottles, or jugs to dropper bottles, vials, or other products. Set on casters to roll easily to a filling or packaging line, the portable bottomless conveyor is typically installed above a printer to automatically apply lot traceability coding on the bottle bottom, or anywhere that bottle spacing, speed control, or powered transfer from one stage in the line to another stage is needed.

The BCV1 captures bottles from an adjoining conveyor and gently suspends them between the hugger belts while advancing them to discharge onto a turntable or conveyor downstream.