Walmart has announced it’s building a $350 million milk processing facility in Valdosta, Ga., which will break ground later this year. Scheduled to open in 2025, the plant will increase Walmart’s capacity to meet high-quality milk demand while making its supply chain more resilient.

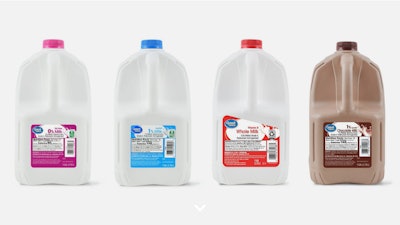

Using ingredients sourced from local farmers, the plant will process and bottle a variety of milk options, including gal, half-gal, whole, 2%, 1%, skim, and 1% chocolate milk under the Great Value and Sam’s Club’s Member’s Mark brands, for more than 750 Walmart stores and Sam’s Clubs in the Southeast.

The plant will create approximately 400 Walmart jobs in the Valdosta community. Walmart opened its first milk processing facility in Fort Wayne, Ind., in 2018. The company also has case-ready beef facilities in Thomasville, Ga., and Olathe, Kan.

| Most Dairy Processors Outsource Some Services |

“We’re excited that Walmart will soon tap into Georgia’s No. 1 industry and open new opportunities for farmers in the Lowndes County area,” says Governor Brian Kemp. “Congratulations to all those on the local and state level whose hard work made this announcement possible.”

The Georgia Department of Economic Development’s Global Commerce team worked in partnership with the Valdosta-Lowndes County Development Authority, City of Valdosta, Georgia Department of Agriculture, Georgia Power, and Georgia Quick Start to secure the Walmart project.

“We’re thrilled to open this new dairy facility in Valdosta, Georgia, as we continue to make strides to increase surety of supply for our customers’ grocery essentials,” says Bruce Heckman, vice president of manufacturing at Walmart. “We’re looking forward to breaking ground on this exciting venture, and we’ll continue to work alongside local dairy farmers and associates as we move ahead. Their collaboration is critical to ensure we’re operating a facility that will process high-quality milk for our customers.”