This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

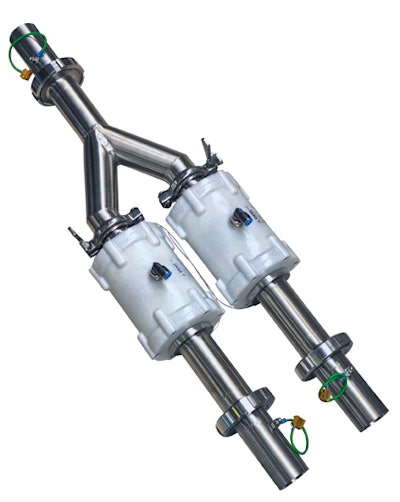

Diverter valves from process equipment manufacturer Volkmann USA, Bristol, PA, feature stainless steel construction to permit installation in food, nutrition, pharmaceutical, and other sanitary bulk material handling processes.

Installed with the company's pneumatic vacuum conveying systems, the diverter valves split a single material stream into multiple streams to load multiple hoppers, feeders, mixers, vertical form fill seal machines, or other equipment at the same time. Conversely, the sanitary diverter valves may be used to transfer multiple materials from multiple locations to a single location. In either configuration, the diverter valves streamline the conveying system and reduce the complexity of material handling infrastructure for improved efficiency and versatility.

Ideal for transferring powders, pellets, mixtures, and other dry, bulk solids, the hygienic diverter valves are fabricated from a choice of 316L or 304 stainless steel in product contact areas with smooth internal surfaces and no pinch points or internal cavities to prevent buildup or contamination. The valves excel in continuous conveying and may be shifted on the fly without interrupting the material flow.

The diverter valves may be pneumatically or electrically activated and/or seamlessly integrated into existing PLC-based control systems. Optional FDA- and ATEX-compliant models are available.