This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

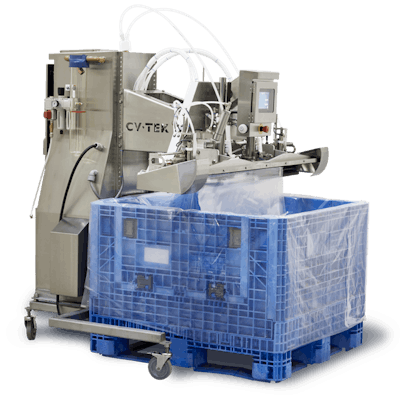

CV-TEK, a Middleby Food Processing brand, proudly introduces the MAP-VAC Bulk Bin Roll Around, an advancement in Modified Atmosphere Packaging (MAP) technology. Designed to preserve, protect, and extend the shelf life of a wide range of products, this equipment is an essential addition for modern food processing facilities.

The MAP-VAC Bulk Bin Roll Around is versatile, accommodating packaging needs from 5 to 2000 pounds, making it ideal for products including poultry, beef, pork, prepared meats, cheese, produce, nuts, and industrial powders. This flexibility, combined with its ability to use vacuum and gas flush techniques, significantly extends shelf life and enhances product quality by preserving flavor and reducing weight compared to traditional ice packs.

For facility owners and senior management, the MAP-VAC offers extended shelf life and flavor preservation, lower shipping weight, and increased distribution reach, while reducing energy costs by eliminating freeze/defrost cycles. Project engineers will appreciate the 100% stainless steel construction, compliance with FSMA, FDA, and USDA standards, built to IP69 specifications for wash-down readiness, with customizable seal bar lengths. Options for vacuum pump, liquid-ring, or venturi systems ensure flexibility and efficiency.

Service technicians benefit from easy access to components with clean-in-place sanitation, self-diagnostic B&R PLC for easy maintenance, and comprehensive manuals and detailed schematics for support. The MAP-VAC stands out with its robust design, built to withstand harsh environments, operating efficiently across three shifts per day, year-round. This reliability ensures it fits seamlessly into Middleby Food Processing’s complete line solutions, maximizing product protection at the end of the production line.

CV-TEK's legacy is built on continuous innovation, exploring new markets, and adapting to customer-driven needs. This commitment is reflected in their ongoing development of equipment that meets the highest standards of sanitation and sustainability, with a focus on improving throughput and profitability.