This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

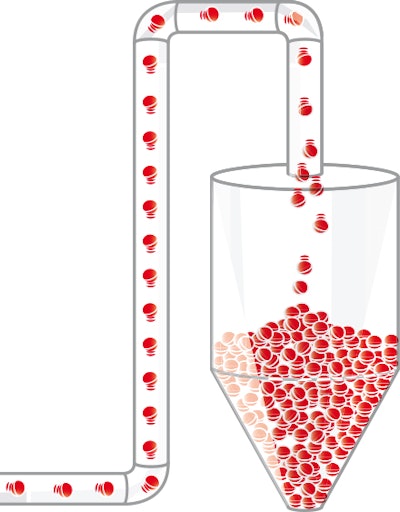

The Gericke Pulse-Line PTA PL pneumatic conveying system automatically transfers powders, pellets, and other bulk materials up hundreds of ft of vertical lift for safe, smooth loading of silos, mixers, hoppers, reactors, and other discharge points set high off the floor or ground. Featuring a patented design, the dense phase Pulse-Line PTA PL uses one or more high-pressure vessels with an external air injection system to generate the high conveying action up to six barg required to overcome long, vertical distances, yet operates at low gas velocities for gentle transfer. The design ensures material consistently moves forward as pulsed slugs without falling backward down the piping, while safeguarding particle size and shape.

Often specified for transferring food ingredients, chemicals, pharmaceuticals, and other dry, fragile materials and mixtures, the sealed pneumatic conveyor operates without rotary valves or other rotating parts to eliminate concern for metal contamination and air leakage. The pneumatic conveyor system is custom-engineered for each installation and includes the feeding hopper, pressure vessel, pipeline, activators, air supplies, and the company's computer-driven STP 61 touchscreen control system. Optional explosion-proof and sanitary versions are available.