This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

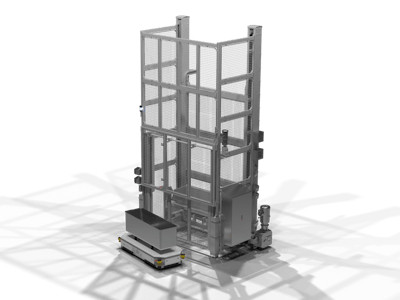

EnSight Solutions is thrilled to announce the launch of a multi-equipment solution designed to automate the dumping and movement of heavy products. Featuring the new Twin Column Dumper integrated with the Staubli Automated Guided Vehicle (AGV) system, this advanced solution addresses labor shortages while significantly improving safety and efficiency in industrial environments.

By seamlessly coordinating product dumping and transport, the system eliminates the need for forklift traffic and reduces manual oversight. When the dumper releases the product into a trough or designated container, the AGV automatically picks up the container and moves it to the next destination. This innovative approach streamlines operations, enhances workplace safety, and optimizes productivity.

Key Features:

- Industrial-proof drive unit for rugged reliability

- Secured safety chain for enhanced protection

- Easy-access components for simplified maintenance

- Human safety scanner to detect and protect personnel

- 5 strategically placed emergency stop buttons

- Advanced collision avoidance system for seamless navigation

Specifications:

- Dimensions: 68.9” L x 38.2” W (1750mm L x 970mm W)

- Height (without lift unit): 13.8” (350mm)

- Height (with lift unit): 15.75” (400mm)

- Payload Capacity: Up to 6,000 lbs. (2,721.6 kg)

- Speed: Up to 5.2 ft/s (1.6 m/s)

- Turn Radius: 5.6’ (1.7 m)

The integration of automation technology minimizes human error, reduces workplace injuries, and creates a smarter, more streamlined process for product movement. Industries such as food processing, manufacturing, and material handling stand to benefit significantly from this innovative solution.