This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

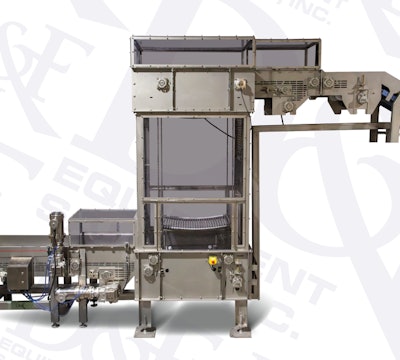

D&F Equipment Sales, a full-service equipment manufacturer and engineering supplier for the poultry, meat, and prepared foods industries, has officially launched its latest innovation: a fully stainless steel, washdown-ready Elevator Conveyor system.

Engineered to maximize vertical space and plant efficiency, this custom-built solution was designed for facilities seeking smarter, more sanitary material handling systems. Standard functionality of D&F’s Elevator Conveyor is 100lbs per carriage and 30 units per minute, but it is customizable to fit specific plant needs with weight, size, and tray capacities.

Key Features of the Elevator Conveyor System:

• Requires minimal floor space to elevate boxes to different heights

• Supports both elevation and decline

• Accepts a wide range of box sizes

• 100% stainless-steel construction for durability and sanitation

• Fully washdown capable to meet strict hygiene standards and streamline cleaning

• Custom-designed for specific elevation requirements

• Includes Indexing Meter Conveyor for proper box loading

• Equipped with a pneumatic stop to control incoming box spacing

• Features a stainless-steel control box

• Control box monitors downstream run signal for seamless integration

• Variable Frequency Drives included

• Stainless-steel drive assemblies utilized

From its flexible elevation capabilities to seamless integration with existing systems, D&F’s elevator conveyor offers a tailored vertical solution that prioritizes efficiency without sacrificing plant real estate or sanitation.

“It takes product up and down the different elevating heights that we can custom build to,” said Mike Williams, Arkansas-based Sales Engineer for D&F Equipment Sales. “Whether your plant layout requires elevation or decline, this conveyor is engineered to adapt to your space and product flow.”

Sanitation was a key design driver, especially for facilities operating under strict food safety protocols. Built entirely from stainless components, the system is fully washdown capable and designed for quick, efficient cleaning. “It allows for fully washdown-ability,” Williams emphasized. This not only supports regulatory compliance but also minimizes downtime during cleaning and maintenance.

The Elevator Conveyor made its debut in D&F’s live, operational showcase at IPPE 2025, where it captured the attention of food processors looking for smarter, space-conscious material handling solutions. With this latest innovation, D&F Equipment Sales reinforces its reputation for custom- engineered systems that solve real-world plant challenges—backed by decades of industry experience and a whatever-it-takes mindset.