This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

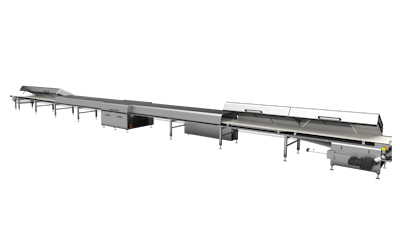

Bühler has introduced OmniCool Smart, a compact, next-generation cooling tunnel engineered for product and chocolate cooling, delivering high product quality in the compact market segment. The new system helps customers cut energy consumption and reduce operating costs through a streamlined, maintenance-friendly design.

“OmniCool Smart is the ideal compact cooling solution for today’s and future production needs. It ensures consistently high product quality, significantly reduces cleaning and maintenance requirements, and supports customers in reducing their carbon footprint,” says András Somfai, Head of Product Management & Process Engineering at Bühler.

Unlike traditional cooling tunnels that rely on compressed air, OmniCool Smart operates entirely on electricity. Compressed air systems are energy-intensive and require regular maintenance. Fully electric systems offer a quieter, more efficient, and low-maintenance alternative, reducing energy use, cutting costs, and supporting more sustainable operations. Additionally, OmniCool Smart optimizes airflow, temperature control, and belt tracking to deliver perfectly cooled fruit, cereal, snack, and protein bars, as well as enrobed wafer and biscuit products, combining superior product quality with enhanced energy efficiency and reduced environmental impact.

Built for effectiveness and easy cleaning

OmniCool Smart features a modular design with the cooling section positioned underneath, ensuring optimal cooling performance while minimizing overall height. Its innovative belt tracking system incorporates the latest sensor technology to deliver ideal operating conditions. Designed for easy maintenance and cleaning, this cooling tunnel reduces downtime and enhances overall equipment effectiveness.

Seamless integration and user-friendly operation

OmniCool Smart is designed for full integration into existing production lines. It can be operated either from the previous machine in the line or directly via its own control panel (human-machine interface, HMI). PlayOne HMI visualization software reflects Bühler’s user-centric design philosophy, enabling efficient, safe, and seamless interaction with the system. Operators benefit from intuitive controls that simplify configuration and monitoring, both at the equipment or via smart devices.

Higher efficiency, lower impact

In line with Bühler’s purpose of “Innovations for a better world,” OmniCool Smart is built to reduce energy use and minimize environmental impact. Its efficient insulation and airtight seals help prevent energy loss, while the fully electric design eliminates the need for compressed air, lowering energy consumption. This translates into reduced operating costs and a smaller carbon footprint.

OmniCool is also available as a bundle with ChoCoat Pro, offering an optimized solution for enrobing and cooling. Bühler’s high-quality enrober maintains precise temperature control and energy efficiency and is designed for easy cleaning and maintenance. Together, the two systems enhance both process efficiency and product consistency.