This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

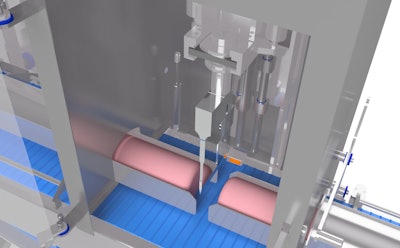

The new Deville Technologies portion cutter facilitates the reduction of a variety of products that come in a rectangular loaf format (such as sausage and mozzarella), which are subsequently fed to a downstream dicer or a centrifugal shredder. The portion cutter uses an indexing motor coupled with an ultrasonic blade to ensure clean and consistent cuts.

The ultra-hygienic, ultrasonic blade is specifically designed to cut an array of products, ranging from extremely soft and/or sticky in texture, to firmer products. While the vibration allows for precise, clean cuts even when cutting soft textures (such as cheesecake), the robustness of the blade allows for minimal maintenance and changeover. The equipment was designed with hygiene and quality top of mind—the blades are in stainless steel (304 construction), and the welds are polished to Ra32 (34 finish). The portion cutter is also equipped with a human-machine interface (HMI) screen to facilitate recipe settings and storage.

The portion cutter can be integrated into a line or used as a standalone machine for product preparation. If it is not integrated on the plant floor and being used for product preparation, it can communicate with a floor scale.