This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

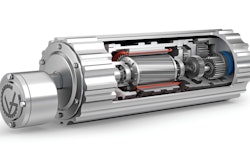

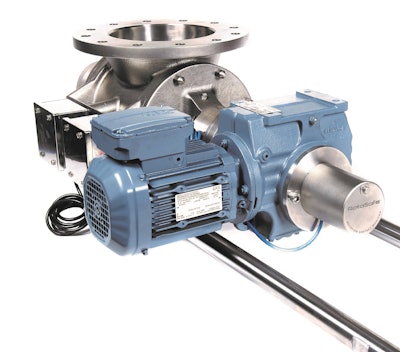

Process equipment manufacturer Gericke USA has introduced the RotaSafe RS1 valve rotor protection system. Developed to protect food, pharmaceutical, and other ingredients from metal particulate contamination, the new RotaSafe RS1 monitors rotary valve operation 24/7, automatically detects contact between the rotor and housing and, in the event of detection, immediately shuts down power to the drive motor to stop the process. The rotary airlock safety system is triggered before the powders or other bulk materials can become contaminated by foreign matter and before the valve incurs any damage from metal to metal contact.

Based on the company’s proprietary RotaSafe technology, the RotaSafe RS1 features new programming and state-of-the-art amplification hardware for enhanced functionality and superior control over detection accuracy, security, and other parameters. The latest RotaSafe RS1 rotary valve protection system is included as standard equipment on the company’s line of rotary valves and may be retrofitted on existing Gericke RotaVal valves in the field.