This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

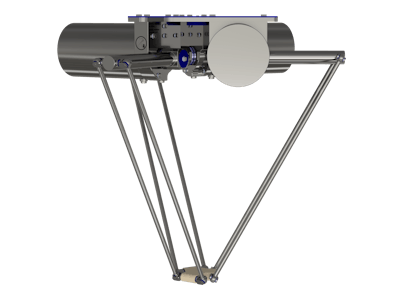

In the ever-evolving landscape of food production and processing, maintaining stringent hygiene standards while maximizing efficiency is a top priority. The DELTA Hygienic Design (HHD) robot is specifically engineered to meet these demands, making it an invaluable asset for industries such as dairy, fish, meat, and poultry processing.

Key Features of the DELTA Hygienic Design (HHD) Robot

The DELTA HHD robot is designed with technology to ensure optimal performance in highly regulated environments. Some of its standout features include:

- Open Mechanics: This allows for seamless integration with different control architectures, offering flexibility to meet diverse automation needs.

- IP69K Compliance: The robot can withstand high-pressure cleaning of up to 28 bar (400 psi), ensuring thorough sanitation in food processing environments.

- FDA-Compliant Materials and Lubricants: All components meet food safety standards, preventing contamination and ensuring compliance with industry regulations.

- Motor Encapsulation (Varies by Model): Some models feature motor encapsulation for additional protection against contaminants.

- High Rigidity: Designed for superior repeatability and accuracy, essential for tasks requiring precision handling of food products.

Variants and Specifications

The DELTA HHD robot is available in different configurations to suit various operational requirements:

- Degrees of Freedom (DoF): 3 to 4

- Nominal Payload: Ranges from 1 kg to 12 kg (2.2 lbs to 26.5 lbs)

- Working Area (Diameter): 800 mm to 1600 mm (31.5 in to 63.0 in)

These specifications ensure adaptability to different production lines and product types, making the robot a versatile solution for automation.

Ideal Applications

The DELTA HHD robot is particularly well-suited for use in environments that require both efficiency and stringent hygiene standards. Below are some of the industries where this robot excels:

Dairy Industry

In dairy production, contamination control is critical. The DELTA HHD robot can be used for handling cheese, yogurt packaging, milk cartons, and other dairy products. Its FDA-compliant materials and ability to withstand rigorous cleaning processes make it ideal for such applications.

Fish Processing

Fish processing involves handling delicate and perishable products. The robot’s precision ensures accurate cutting, sorting, and packaging while maintaining food safety. Its high-pressure cleaning resistance also allows for easy sanitation between processing cycles.

Meat & Poultry Processing

In meat and poultry processing plants, the DELTA HHD robot can be utilized for tasks such as portioning, deboning, and packaging. The high-speed handling capability and strict hygiene compliance help streamline operations while maintaining the highest standards of food safety.

Conclusion

The DELTA Hygienic Design (HHD) robot is a game-changer for the food industry, offering a perfect blend of automation, precision, and hygiene compliance. With its robust design, adaptability, and seamless integration options, it ensures efficiency while meeting the rigorous sanitation standards required in food processing. Whether in dairy, fish, or meat and poultry industries, the DELTA HHD robot is an indispensable tool for optimizing production while maintaining food safety and quality.

Find more information at www.autonox.com.