Quick hits:

- Redzone helps food and beverage processors with labor training and engagement by providing game-based user interfaces.

- Netzsch’s technology focuses on progressive cavity pumps and sanitary design pumps.

- PepsiCo Launches Campaign to Help Latina-owned Businesses

- Frito-Lay Achieves Ambition for a Quieter, Industrially Compostable, 100% Bio-based Snack Bag

| Read the transcript below: |

Joyce Fassl: I’m Joyce Fassl, senior executive editor of ProFood World, with an update on new food plant production projects in the US.

Nestlé USA is investing $675 million to build a new beverage facility in Glendale, Arizona. The factory will produce creamers for Nestlé's portfolio, including the Coffee mate, Coffee mate natural bliss, and Starbucks brands, with the ability to expand to additional beverages in the future.

The 630,000 square foot facility will be designed with a focus on sustainability, including a water recycling process to reduce water usage, zero waste to landfill, and fully recyclable product packaging made from food-safe, recycled plastic. Also, in support of the company’s goal to attain zero environmental impact in its operations by 2030, the facility will strive for 100% renewable energy by 2025.

Kerry Group recently expanded its manufacturing facility in Rome, Georgia, doubling the site’s capacity.

The 316,000 square foot facility provides integrated taste and nutrition solutions to help customers meet growing consumer demand in the poultry, seafood, and alternative protein markets, across the U.S. and Canada.

Kerry Group also prioritized sustainability initiatives across the facility, including the use of 100% renewable electricity, zero waste to landfill, bulk receiving of materials, local sourcing where possible, and the extensive use of energy-efficient equipment.

PepsiCo Beverages North America, a division of PepsiCo, is investing $260 million to expand its manufacturing facility in Tucker, Georgia. The 260,000 square foot plant expansion project will make the facility one of the company’s largest, and will increase the facility’s productivity five times over its current output. It will be the company’s most technologically advanced factory and distribution center.

Please stay tuned for my report on some of the new technologies seen at the recent PACK EXPO East show in Philadelphia.

Joyce Fassl: I'm Joyce Fassl, Senior Executive Editor of ProFood World. And today I'm in my hometown of Philadelphia at PACK EXPO East. So I just wanted to give you a brief overview of what I've seen on the first day of the show here Monday, March 21. Some of the themes I've been seeing are employee engagement, operational efficiency, sanitary design. So let's take a look at some highlights of what I've been seeing this week.

Osvaldo Granillo: So right now what we're seeing in the labor market is really things have the tables have turned this labor shortage, there's a lot of different variables that we aren't able to track people in manufacturing, we can look at it that there is the image problem and manufacturing that I believe only about 27% of parents believe that manufacturing is a suitable industry for their kids to go work in. But then we have these Gen Z and millennials coming into the into the area. So what this means is that they're not having technology in their hands, they don't see it as a nice to have, they're seeing it as a must have. So a lot of times in manufacturing facilities are coming in and it's very archaic. So what can we do as manufacturing facilities to engage our people make work more fun, and show them that this is a suitable area to work in. Most organizations are only increasing their pay when in reality by the Deloitte and Manufacturing Institute study that ranks as number 14 on the list. In reality, they want to make sure that they're making an impact what they're doing is for the greater good, and that they're part of a team environment. So what we do at Redzone is we connect everyone in the operations we incentivize them by different through the technology you can see behind me as well as gamifying getting making it more fun to come to work every day. It's a lot nicer when you can come to work in manufacturing and know if you did a good job or a bad job for the day. So connecting different departments and giving them a voice out on the shop floor is what we're doing out here at Redzone.

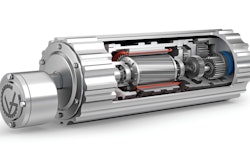

Robert LePera: Hello, I'm Bob LaPera, Vice President OEM sales for Netzsch Pumps North America and this is our booth at the PACK EXPO East in Philadelphia. Netzsch is the largest producer in the world of progressing cavity pumps, both industrial and sanitary versions as you can see here and we have multiple design versions of the pump depending on the type of application that you have going from anywhere from very light fluid to very heavy viscosity and high density materials. Were also a leader in the world of multiple screw pumps and rotary low pumps all available in three sanitary versions.