There are different methods of applying primary coding, which is a series of alphanumeric characters or codes that can be applied directly to packaging, including paper, plastics, glass, and steel.

Used for track and trace and serialization, primary coding has two important factors: cost per mark and speed at which the mark can be applied. In the food and beverage industry, there are different ways to apply primary coding, which are continuous inkjet, thermal inkjet, and laser. Each, of course, have pros and cons when it comes to cost, resolution, and throw distance—which is how far the print head can be from the product.

Continuous inkjet (CIJ), printers cost between $6,000-$13,000, have a resolution of about 64 dpi, and a ½-inch throw distance. It’s good for round or recess surfaces when product control is not as critical. The CIJ also often requires service, making the cost per month a combination of ink, makeup solution, and maintenance.

Thermal inkjet (TIJ) has a median capital cost of between $1,000-$2,000 per printer, a resolution of 1,200 dpi horizontally, and a 1/8-inch throw distance, which means round objects are a challenge to print on. But TIJ can print small text and large graphics at same speed. And speed can be enhanced with interlaced cartridges. TIJ also require little to no maintenance as the cartridge is the print head which just needs to be replaced.

Lasers cost between $20,000-$30,000 (with a lifespan of up to 40,000 hours) for CO2 lasers and $30,000-$50,000 (with a lifespan of up to 100,000 hours) for fiber lasers. It uses ablation, so there is no resolution, and throw distance has a 4-to-6-inch range. Message speed depends on what is being printed. Lasers are not universal and must be matched to the substrate, which means packagers may not find a single laser to handle all of their needs.

Based on the printer landscape, Matthews Marking Systems says that thermal inkjet can play a larger role in primary coding, particularly due to its ability to print 2D codes at high speeds. This plays into a megatrend in the manufacturing industry that moves beyond just track and trace and serialization requirements and considers another emerging area, called “market feedback,” that takes into account customers with a smartphone who use QR codes on products to engage with the manufacturer.

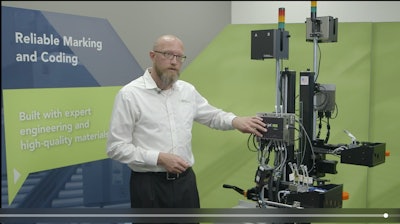

To that end, robust bulk systems and rumors of long throw cartridges emerging are overcoming the inherent obstacles of TIJ. At PACK EXPO Connects, Matthews Marking's global product manager Raymond Fortuna explained the company's unique approach to bulk systems, introducing what it calls the Active Bulk Ink System (ABIS), which uses computer processors, sensors, and accelerometers to ensure accurate performance.

ABIS has two pieces, the main unit is a series of valves all mounted to the processor that is constantly delivering ink to the cartridges. And the cartridge sensor module is an individual unit, always monitoring the cartridge conditions. Atmospheric changes can affect the internal make up of cartridge, but the ABIS’ use of a series of sensors and processors ensure that, as the environment changes, the delivery of the ink changes as well.

To view the Matthews Marking demos (available through March 31, 2021), and to add Matthews to your MyConnects Planner, click here.