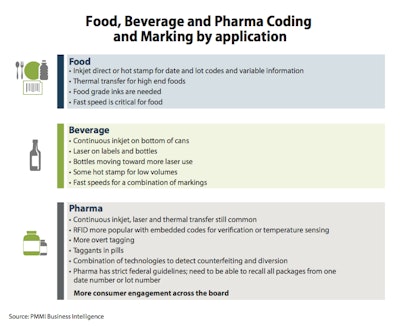

Inkjet and laser are most prevalent, but thermal transfer continues to gain interest, particularly for incoming ingredients. Challenges include limited space on package hamper efforts to add QR codes or aggregation information. Tamper-evident technology has to work in conjunction with marking and coding. New products, new flavors and new materials continually increase complexity and accelerate timelines.