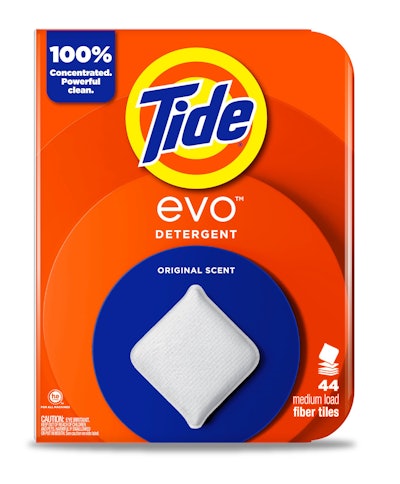

Procter & Gamble (P&G) brand Tide, has launched a new form of laundry detergent called Tide evo, which is a square-shaped, six-layer “tile” of concentrated ingredients woven together. The design of the thin, malleable fiber tile was driven by consumer insight and with sustainability in mind.

"Tide evo embodies over a decade of research and development, signifying a major advancement in how we approach cleanliness and efficiency in our daily lives," says Sundar Raman, chief executive officer, P&G Fabric & Home Care.

P&G’s research found that consumers expect increasing levels of convenience. The company’s response was to develop the Tide evo fiber tiles, which are lighter, faster, and simpler than its other detergents. To be evermore environmentally conscious, the tiles are also designed using tens of thousands of miniscule fibers to create layers of soap without extra liquid and fillers while eliminating the need for plastic bottles. This new detergent dissolves upon contact with water.

Innovative packaging design for ease of use

The fiber tiles, measuring approximately 3.5 x 3.5 in., are packaged in a hinged-lid paperboard carton that is approximately 3.5 in. W x 5.7 in. D x 7.1 in. L. The carton is stored upright on the shelf and opens on the right side, after a perforated strip is removed. A click tab enables easy opening of the package for access to the tiles. It also allows the carton to be securely reclosed.

Inside is a specially designed tray with one partition that separate the tiles into two stacks. The trays provide structural support to the carton, so it maintains its shape from factory to consumer home, while simultaneously keeping the tiles securely stacked. The trays ensure the integrity of both the product and the package’s squareness, according to Marcello Puddu, senior director of Fabric Care Research & Development at P&G.

| Continental Optimizes Corrugated Timing Belt Packs, Fairfood Packs Oat Drink with Paperboard, Borough Broth in Corrugated Thermal Packaging |

“The cartons are initially die-cut into 2D blanks and then partially assembled by our supplier. This partial assembly ensures a seamless process where the cartons are fully erected and filled with Tide evo tiles concurrently, streamlining production,” says Puddu. The Tide evo fiber tiles are lighter, faster, and simpler than its other detergents.

The Tide evo fiber tiles are lighter, faster, and simpler than its other detergents.