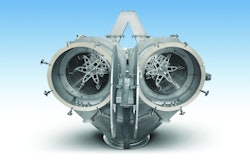

Munson RDC-2424-MS De-Clumper rotary lump breaker

The Munson RDC-2424-MS De-Clumper rotary lump breaker breaks chunks of agglomerated abrasive or friable materials that have compacted during storage or shipment. Material entering the 24-in.-square inlet is reduced in size by dual rotors with three-point, single-piece, abrasion-resistant steel breaking heads rotating above a curved, perforated bed screen. On-size material exits through 1-in. diameter apertures in the bed screen. Powered by a 7.5 HP motor with gear reducer, plus a chain and sprocket drive, the synchronized shafts rotate at approximately 120 rpm. The lump breaker is available in 304/316 stainless steel, finished to sanitary standards for food and dairy applications.

Companies in this article

Videos from Munson Machinery Company, Inc.