As COVID-19 continues to rear its head across the U.S., food and beverage manufacturing plants have had to alter the way they do business, shifting from foodservice and restaurant-focused products to retail goods while employing lots of new technology. As a result new suppliers to the industry have popped up as well, with products including handheld and walk-through temperature scanners, temporary outdoor structures to protect employees from harsh weather conditions as they wait for temperature checks, touchless door sensors and time clocks, and plexiglass partitions to keep employees safe both on the plant floor and in the cafeteria.

AIB International launched the Pandemic Prepared Certification, the first certification standard created for the food and beverage supply chain that elevates critical planning for people, facilities, and production. The company collaborated with government, academia, international agencies, and top brands to develop the standard for the following proficiency areas: Pandemic Crisis Management, Supply Chain Management, Intermittent Operations Planning Management, Health Crisis Mitigation Measures and Management, and Pre-Requisite Program Review. Learn more at www.aibinternational.com.

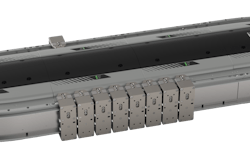

Nestlé has expanded its use of augmented reality (AR) technology to remotely support its production and R&D sites as well as connect with suppliers. The company and its suppliers are using remote assistance tools, including smart glasses, 360-deg cameras, and 3-D software, to work on complex projects at its facilities around the world. Nestlé has used these various AR technologies to set up or redesign production lines and carry out vital maintenance with suppliers.

For example, R&D teams in Switzerland remotely worked with employees at a Nestlé factory in Thailand to upgrade existing production lines and install new production lines and technologies that make ready-to-drink dairy products. AR tools also helped Nestlé install a production line at a facility in China that makes infant cereals and a pet food line in the U.S. In addition, the company used AR to help with maintenance at its factories in Colombia and Ecuador.

Nestlé is transforming its operations by digitalizing its supply chain and manufacturing. The goal is to create a competitive edge through data, artificial intelligence, automation, and predictive analytics, according to the company.

“The remote support approach isn’t just a response to COVID-19 though. Going forward, remote assistance will become a new way of working,” explains David Finlay, global head of manufacturing at Nestlé. “It will increase speed and efficiency in facilities and reduce travel to Nestlé sites, helping us reduce our CO2 emissions across our operations.”