Recent natural disasters, such as Hurricane Ian in late September, have shown the continued importance of planning and preparedness. Some businesses are required to have a hurricane emergency action plan to meet requirements under Federal Emergency Management Agency (FEMA) regulations, and training is an essential component of any adversity recovery plan.

The same kind of preparedness is prudent when it comes to food recalls. For foods regulated by the U.S. Food and Drug Administration (FDA), updated regulations can be found in the Food Safety Modernization Act (FSMA) regulations, which states that facilities must have a written recall plan that includes procedures and steps to do the following: notify their consignees about the recall, notify the public about the hazard, notify the FDA, conduct checks to verify the recall effectiveness (retrieval of product), and appropriately dispose of the recalled food. Triggering and conducting a recall is still a voluntary act that is up to the company. However, the FDA now has statutory authority (under the FD&C Act) to mandate a company recall if the company refuses to do so and the FDA deems it necessary to protect public health by preventing an adulterated or misbranded product from remaining in the marketplace.

Many of the misbranded food recalls consumer packaged goods (CPG) companies deal with (typically greater than 40%) are due to the presence of undeclared allergens on the label. The estimated cost to the company of a recall could be in the millions of dollars, so it is easy to see why CPGs need to get serious about recalls and recall training efforts. Planning and preparedness are key to minimizing the impact of a food recall, and it is the task of the food safety team to create and manage the company’s food safety programs to prevent, plan, and prepare for such an event as a food recall.

When a problem occurs, a company should internally decide if and when a recall is necessary. In some situations, the company might consider that an internal action is warranted when there is no or very limited public exposure to the problem. The decision needs to be made about whether it can be managed through an internal correction, stock recovery, or market withdrawal of product. However, a company must consider a recall when its product or ingredient is adulterated or misbranded, requiring the company’s removal or correction of a marketed product that the FDA considers to be in violation of the laws it administers and is a threat to public safety. Also, the company must take several steps while handling a recall: notify the FDA when a recall is eminent by using the FDA’s Reportable Food Registry portal, notify the company’s supply chain with details, prepare and notify the public via press release(s), conduct a product recovery, correct the problem, and draw an end to the recall.

Managing a recall takes preparation, planning, and practice. Some companies might never experience a recall situation, but every CPG company must nonetheless have plans in place and be familiar with the basic steps that must be taken to quickly and efficiently implement a product recall and product retrieval. If the decision to recall is not readily apparent, it might be wise to engage experts, risk consultants, and legal professionals as needed.

Recalls do not all pose the same risk to the public, therefore the FDA has classified recalls based on certain risk characteristics and it has defined recalls into three classes. The FDA classifies the recall level, not the company. Recalls are classified into a numerical designation (I, II, or III) by the FDA to indicate the relative degree of health hazard presented by the product being recalled.

When products are involved in a recall, it’s almost always a complex situation and logistically difficult. There needs to be a good communication flow between producers, processors, manufacturers, distributors, the FDA, and to the end user. Missteps to avoid during a recall include these don’ts: delay actions unnecessarily, allow financial aspects to affect safety considerations, short-change the scope of the recall resulting in additional recalls, be vague or opinionated with recall language, and don’t admit fault until the investigation is completed.

One element of a recall program is to define the root cause so that production can resume as quickly as possible. Once corrective actions have fixed the problem, the food safety team should analyze the effectiveness of the recall and conduct a Lessons Learned activity to ensure any errors in planning, preparedness, and performance can be avoided in the future. Updates to recall training could be necessary to improve future recall performance.

Recall Team: A well-prepared and well-trained recall team is essential to ensure that recalls are handled quickly and efficiently with the least possible company disruptions and a minimal impact on public health. The preferred team would be composed of a president or CEO, recall coordinator, plant operations manager, food safety and quality manager, product logistics manager, communications and public relations spokesperson, legal counsel, finance, and sales and marketing head.

Of the individuals involved, the key role is the recall coordinator—a team leader responsible for initiating and coordinating the safety aspects or quality investigations of the incident. This person’s job is to develop the recall plan, manage the decision-making process (does the problem justify a recall or perhaps another action, like a market withdrawal), manage the timing of events, and provide training to the team before a recall happens.

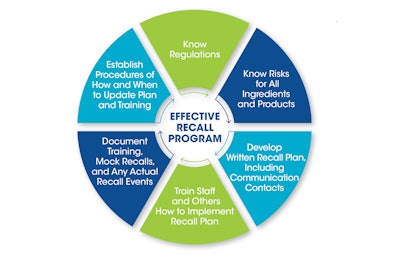

Recall Plan: The coordinator develops the company’s recall plan and training activities that can proceed to ensure all members of the recall team know their responsibilities and understand their respective roles. A measure of the plan’s effectiveness can be evaluated after conducting a mock recall. Deficiencies in the plan can be identified and eliminated through a process of continuous improvement.

Team Training: Training methodologies are many, and a company might choose to conduct training internally or engage outside resources to assist with training of various recall program components. A well-written and comprehensive recall plan is essential to provide the backbone for a training template, leading to a successfully trained recall team.

Some considerations should be made while designing the training program. First and foremost, C-level executives must be willing to allocate the necessary time and resources to the training program and allow the necessary maintenance and follow-up activities. A further consideration is based on the differing characteristics of the various recall team members. For example, some team members might require training in a different language to fully comprehend their roles and responsibilities. A team member’s age might play a factor in how they best receive and absorb the materials taught. People have different levels of reading skills, understanding, and comprehension; therefore, sometimes one-sized training is not effective for all. The training environment—such as room size and shape, lighting, seating, noise level, A/V equipment, use of online activities, and use of written and visual materials—all play a part in maximizing learning and retention.

Most of the employees to be trained will be adults. Some scholars have made assumptions and recommendations about how best to train adults based on how adults prefer to learn. It has been suggested that by understanding the principles of adult learning, one can design a workplace training program that enhances the learning experience and maximizes its effectiveness. Adults often learn best when they can relate the new material to what they already know. Learners need roadmaps with clear objectives. Each new piece of information needs to build logically on the current situation.

An essential function of post-training is to conduct a mock recall to test the readiness and effectiveness of the recall team to react correctly and in the best interest of the company and public health. Some additional training or modifications to the recall plan might be necessary to improve the overall outcome of the mock recall training experience.