A new RFID feature available on machines from Douglas Machine lets users of the equipment decide not only who is authorized to access a machine’s operating parameters but also the level of access permitted.

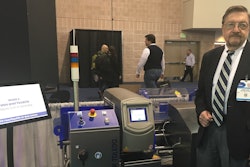

The RFID reader comes from the pcProx® family of readers made by RFIDeas, which is a Rockwell Encompass Partner. Measuring about 3 x 5 in., the reader gets mounted on the side of the enclosure that holds the Rockwell Panelview 1000 HMI. The reader is connected to the machine’s Ethernet network for communication to the Logix processor and PanelView Plus HMI. Software is written to provide Douglas’s customers with on-machine administration for RFID key assignments and access levels. The HMI provides the customer with an interface for assigning RFID “keys” (they’re actually fobs or cards) to individual users, along with security access levels.

“Having individual users log in by way of RFID enhances security for the HMI and also lets customers track parameter changes,” says Steve Lipps, Senior Director of Product Management at Douglas Machine. “Many customers have stories of how uncontrolled access can create operational issues or can make troubleshooting feel like running in circles. As for parameter change tracking, it creates and maintains a log of changes in machine parameter values and identifies the recipe, the parameter, values before and after a change, the date and time a change was made, and the logged-in user making the change. This information can be very helpful in diagnosing issues. For example, if a parameter related to the dimensions of a case is constantly being changed, it could point to an issue with the quality of the corrugated cases being supplied.”